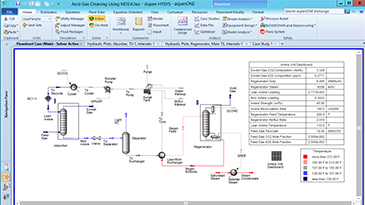

Acid gas removal is a crucial step for eliminating sulfur, carbon dioxide and other impurities from natural gas and natural gas liquids to meet environmental regulations and fungible product specifications.

But acid gas removal units are tricky to design and often operated inefficiently. There are a number of opportunities to predict and resolve bottlenecks and minimize solvent and energy use to reduce costs — all while assuring requirements are consistently met. Engineers can take advantage of these opportunities with a better understanding of the unit, and that is where Aspen HYSYS comes in.

Initially released in Aspen HYSYS V8.3, the new Acid Gas technology has grown with subsequent releases and the addition of new solvents, property packages and functionalities. With the level of activity around Acid Gas Removal Optimization in Aspen HYSYS over the last few years, it is hard to keep track of what is available with Aspen HYSYS and what problems it can help you solve.

Here are a few answers to the top questions we get around this technology. (If you would like to see the full list, please read Top 10 Questions About Acid Gas Removal Optimization with Aspen HYSYS, or you can sign up for the our upcoming webinar and ask your own questions!)

Q: Is Acid Gas in Aspen HYSYS rate-based technology? Can it help me identify and address bulge-pinched and lean-pinched columns?

Yes, Acid Gas in Aspen HYSYS accounts for not only kinetic reaction rate-based modeling, but it also accounts for mass transfer resistance. The Acid Gas technology provides Efficiency Modeling mode and Advanced Modeling mode for different levels of model fidelity. Advanced Modeling mode can be used to identify bulge-pinched and lean-pinched absorber columns. You can plot absorber temperature by stage in Aspen HYSYS and see the corresponding efficacy of the absorption. You can just plot the partial pressure of H2S or CO2 by stage in the vapor vs. aqueous phases to see if the column is pinched.

Efficiency Modeling mode accounts for mass-transfer resistance at the vapor-liquid interface to calculate “rate-based” efficiencies for H2S and CO2. This mode allows the HYSIM I/O algorithm to be used in the column. The Advanced Modeling mode accounts for mass-transfer resistance at the vapor-liquid interface to calculate the flux of all components using the rate-based distillation directly.

Q: Can Acid Gas in Aspen HYSYS analyze liquid-liquid and physical solvent systems? What solvents and components does Aspen HYSYS support?

You bet! The Acid Gas – Liquid Treating package supports solvents including MDEA, MDEA + PZ, DGA, DEA and MEA, and it is based on the eNRTL model. The Acid Gas – Physical Solvents package supports DEPG and is based on the PCSAFT equation of state. The Acid Gas – Chemical Solvents package in Acid Gas technology supports solvents including MDEA, DEA, MEA, DGA, DIPA, PZ and TEA. It also supports solvent blends including Sulfolane + DIPA, Sulfolane + MDEA, Sulfolane + MDEA + PZ, MDEA + MEA + DEA and any two chemical solvents. The Acid Gas - Chemical Solvents package is developed with the Peng-Robinson equation of state for vapor phase and electrolyte NRTL (eNRTL) for electrolyte thermodynamics.

All three packages have been extensively validated with customer data and available literature sources. We have published a subset of these analyses in three validationpapers that cover amine solvents, physical solvents and liquid-liquid systems.

Q: Can I consider heat-stable salts?

Yes, absolutely. Acid Gas in Aspen HYSYS supports modeling of several heat-stable salts (HSSs) to model the extent of their presence and their effects on the column performance. The supported HSSs include sodium, chloride, formate, acetate, sulfate, thiosulfate, thiocyanate, phosphate, hydronium and hydroxide.

To learn more, read the full document Top 10 Questions About Acid Gas Removal Optimization with Aspen HYSYS or register for our upcoming webinar.

Leave A Comment