Emissions Management for Refining & Olefins

Track carbon emissions, energy use, taxes and offsets – and guide enterprise action to abate CO2 while maintaining margins.

Enable Your Workforce with Consistent Emissions Data and Models

Executives, operational leaders and technical workers can work collaboratively to monitor GHG emissions, identify bad actors and prioritize actions to meet net zero commitments.

- Reduce greenhouse gas emissions up to 25%

- Meet net zero commitments

- Improve planning effectiveness to optimize between margin and GHG emissions

- Report transparently with sustainability auditing for financial and regulatory purposes

- Use the same data, models and information for all sustainability CXO function decisions

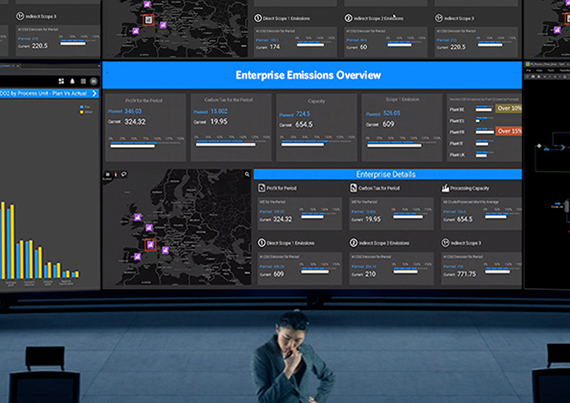

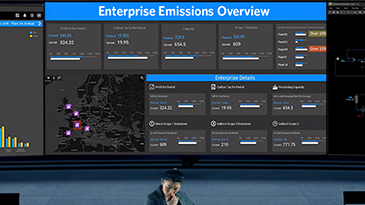

Employ a Decision Support Solution to Reduce CO2 and Improve Operations

Companies are challenged with meeting aggressive abatement targets, visualizing enterprise emissions in real time and prioritizing the right moves to reduce emissions without impacting profits.

AspenTech is helping industry leaders reduce emissions up to 25% by consolidating data into a dynamic visual environment that supports informed decision-making, provides an enterprise view of key metrics and identifies and prioritizes actions to manage and abate carbon emissions.

Key Business Processes to Reduce Emissions

Track & Manage Emissions | Reduce Emissions with APC & Dynamic Optimization | Utilities Optimization

Online & Offline Digital Twins | Planning to Balance CO2 and Profit

.png?h=415&w=675&la=en&hash=CA04A6DC48A7B755D23F8D0BE129B837)