Pulp & Paper

Shifting markets and consumer demands require cost-effective and sustainable production. Our solutions empower efficient manufacturing to reduce downtime, improve quality and stay competitive.

Mills can struggle to increase reliability, safety and sustainability—and operate at maximum potential.

Learn how asset performance management unlocks hidden potential, boosting production, reducing costs, predicting failures and improving quality.

Achieve Overall Equipment Effectiveness (OEE) Goals

- Ensure availability, performance and quality for profitable production of pulp and paper mills

- Increase uptime, efficiency and utilization

- Discover the origin of production losses and improve equipment effectiveness

Avoid Unplanned Downtime

- Reduce maintenance costs and prevent equipment failures

- Minimize energy expenditures to attain your throughput and yield goals

- Operate at maximum potential with improved reliability, safety and sustainability

Improve Product Quality

- Achieve efficient, cost-competitive manufacturing

- Quantify risk while identifying the optimal operating scenarios

- Reduce variability and help achieve on-spec production

Highlighted Solutions and Products

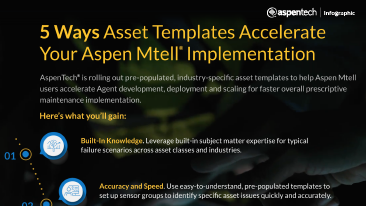

Predict and Minimize the Impact of Equipment Downtime

- Reduce maintenance costs 20-30% per year

- Empower your reliability and maintenance teams

- Increase throughput 1-5%

Optimize across Design and Operations with Aspen Plus®

- Improve performance, quality and time-to-market

- Help advance net-zero goals

- Rigorously model a wide range of chemical processes

Achieve Operational Performance and Sustainability Goals

- Improve throughput by 2-5%

- Increase yield by up to 5%

- Reduce energy consumption by 10%

Scale Digitalization Initiatives with Data Integration and Contextualization

- Collect, aggregate, store and retrieve large volumes of data

- Contextualize data for any system, application or user

- Centralized security, data governance and access control

Unlock the Value of Operational Data and Drive Performance Improvements

- Increase efficiency, productivity and visibility into plant operations

- Real-time asset analysis and monitoring

- Improve product quality up to 30%