Aspen Process Pulse™

Receive early and accurate warnings of product health issues to optimize and improve product quality, reduce waste and support PAT in compliance with regulatory requirements.

Fulfilling R&D and Production Quality Needs

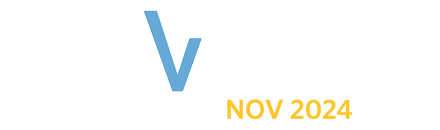

Deliver Quality Product Faster

Enable real-time release testing and reduced waste with real-time product quality monitoring.

Real-Time Data Analysis

Get the most out of current resource investments by analyzing sensor and quality data in real time with direct import from online instruments or through historians like Aspen InfoPlus.21®.

Ensuring Process Quality

Take advantage of full process visibility, early fault detection and process deviation warnings. Use powerful multivariate analysis to build process models for improved efficiency and prediction of process quality.

PAT Portfolio Honored with a Pharma Manufacturing 2021 Innovation Award

The award celebrates technologies contributing to advancements in risk reduction, product quality improvement and manufacturing efficiency.