Do you struggle to effectively utilize maintenance records inside your enterprise asset management (EAM) system? If you do, it’s likely because these records are not being used after the work has been approved and completed — so you’re not really tapping into the value of that data!

There’s a better way to stay current on maintenance records and use them to drive value across the enterprise. It starts with a timely and precise message like this:

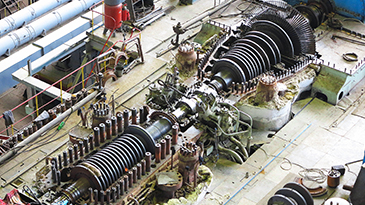

“Alert – Critical Turbine has a valve problem.

This problem will cause a failure in the turbine in 32 days if a repair is not made.

Please see Maintenance Plan 1234 for resolution.”

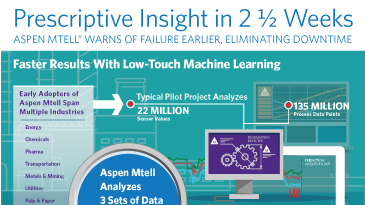

This is what you get when you have prescriptive technology embedded in your EAM system. Prescriptive technology allows for both the early alerting of issues in a process or piece of equipment as well as the identification of the problem, cause and remedy for the issue identified.

In this case, the maintenance worker would inspect the valve to confirm the leak and consult with the plant manager. They could then execute a planned maintenance package earlier, thereby removing the need to do another preventive maintenance (PM) and effectively saving the cost of the latter PM package.

And that’s just half of the benefit. The rest of the payoff comes when the maintenance worker updates the maintenance record with the repair of the valve. The system then “closes the loop” by incorporating all new maintenance records — and the prescriptive technology is able to learn from this data and improve its early-prediction capability.

A system like this also standardizes the record-updating process and ensures that accurate and relevant data is recorded for each repair. In an integrated solution with prescriptive technology, these electronic maintenance records help build the prescription, accurately tell the story of the failure or anomaly and also provide the remedies that improve the maintenance activity.

The EAM systems hold the PM packages that represent the scheduled maintenance for the critical assets and systems of the plant or process unit. With prescriptive technology providing early identification of an issue and the recommended actions, you gain new levels of predictability and flexibility in maintenance. You can potentially adjust or reduce OPEX, as PM packages can be safely moved out of the current budget cycle.

Leveraging a combination of maintenance data, real-time operational data and an understanding of the upstream processes, prescriptive technologies are enabling companies to continuously improve their maintenance processes. It begins with their ability to communicate directly with the worker: “Excuse me, I have an issue… Come see me please.”

What a nice way to start the day!

Learn how nine companies have used this technology to reduce unplanned downtime and improve asset reliability in the white paper Seeing Into the Future With Prescriptive Analytics.

Leave A Comment