In the ever evolving and interconnected landscape of midstream operations, one of the biggest hurdles faced by companies lies in the gathering and interpretation of measurement data scattered across various sources. From pipelines to terminals, the data journey for midstream producers is often troubled with complexities, making it challenging for decision-makers to collect actionable insights from various sources.

This has historically been a significant challenge for midstream companies due to how widely distributed production measurement data can be. It is important that there is an effective strategy in place to compile this data to create accurate production records. Inaccuracies in production records can directly affect many areas of daily operations. Business units, such as production accountants, sales, marketing and senior leadership, all rely on these records to be as accurate as possible to come to proper data-backed business decisions.

The Complex Data Puzzle

Issues in measurement arise due to the many different datapoints making up production measurement data. Weaving these data points together precisely is difficult not only because this measurement data is often spread out across a variety of different sites and pipeline networks, but also because of the variety of technologies generating reports based on these datasets.

These process data technologies create a complex network consisting of plant and pipeline automation platforms such as SCADA, DCS’s and PLCs. Coupled with these measurement data points are track measurement technologies such as mass flow meters, ultrasonic flow meters, flow computers and remote telemetry units. Making up the rest of this data equation are technologies such as data historians, lab systems, online analyzers, tank gauging systems, meter calibration systems, proving systems and truck/rail shipping systems.

In addition, midstream producers also rely on the inclusion of record data to accurately evaluate these production records. This web of record data also includes product quality data, often provided by third party labs and testing facilities as well as online analyzers.

Metadata is another component to be factored in, which is collected through the automation of SCADA systems that transfer metrics such as flow calculations, product movement and truck/rail loading information. Lastly, a main variable at play within record data is data collected from site calibration and proving systems. Making sure that meters and measuring tools are properly calibrated and adjusted on a specific cadence is essential in qualifying this data as completely trustworthy.

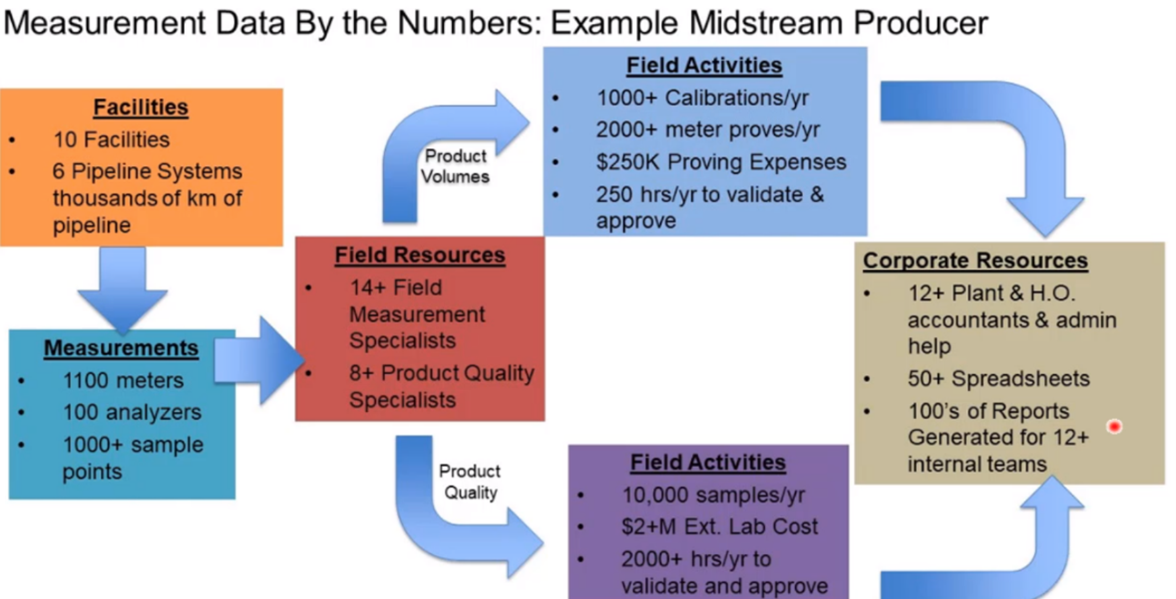

The volume and diversity of data and reports typical midstream producers need to assess and aggregate

Taking a step back and reviewing the many different components making up this equation, the task these plants face to consolidate this data, assure its accuracy and connect and effectively use this data in a timely manner is daunting. Mid-to-large-sized midstream producers literally deal with tens of millions of different data points per day. The profound mass of data collected daily to run an operation creates a large need for technology that establishes a consumable data foundation.

Our Solution

AspenTech Inmation™ offers a solution to connect these different strands of information. Using our solution, midstream companies can connect all these measurement data points on one secure system. Whether it is flow information, orifice change records, calibration records, lab data or proving records, AspenTech Inmation can handle all of this and combine it into a single repository. That data can then be distributed to other software.

AspenTech Inmation provides data aggregation while also preventing common OT connectivity challenges that legacy technology faces. Some of these challenges include gathering multiple data types into a singular database, OT load balancing and bridging data to IT networks and systems.

To learn more, hear experts from AspenTech’s partner, Spartan Controls, as they discuss data management and conduct a demo highlighting AspenTech Inmation’s value to the midstream oil and gas production industry.

.png?h=250&w=975&la=en&hash=3700F6F8CC57A640C9D9940EB09FC052)

Leave A Comment