An unprecedented winter storm hits Texas, and nearly 4.4 million power customers are without electricity. Both renewable and traditional energy sources freeze, temporarily putting an end to power generation in the region. While an investigation is currently underway, one thing is certain: Predictive analysis and maintenance should be a key part of any power generation strategy to help optimize reliability, as well as reduce potential downtime and damage.

Today, challenges such as deregulation, the rapid adoption of renewable energy sources and a new emphasis on extending facility lifecycles are forcing electric utility operators to take a closer look at the way they expend resources and optimize operations. In fact, top performers in the power industry are deploying more effective maintenance strategies—supported by technologies, resources and sound procedures with continuous optimization—to keep their assets performing high on the P-F curve and delivering business value.

The transition to sustainable sources brings with it such challenges as the variation in maintenance needs, as well as dependency on things like weather conditions as seen in Texas this past February. Predictive maintenance solutions play a key role in mitigating risks to human life and the environment. And by taking those early-intervention actions, they reduce the risks for shareholders and stakeholders, as well.

Utility executives are seeing the potential benefits of enterprise-wide digitalization initiatives. Digital technologies, including predictive maintenance and others, are helping them:

- Reduce unplanned downtime by predicting failures with enough time to plan maintenance

- Get quantified analysis of how much an event impacts revenue, providing a clear target for the technology

- Understand the impact on safety and sustainability by avoiding unsafe conditions related to unplanned downtime

- Optimize margins via improved reliability that significantly reduces unplanned downtime

- Enable Industrial AI, which is shaping the future of manufacturing and enabling the journey to the Self-Optimizing Plant (learn more)

Although digitalization efforts within the power industry are on the rise, there are several misconceptions, one of which is that data science expertise is required to make headway in digitalization efforts. True digitalization efforts make use of the domain expertise of existing engineers and other resources within your organization. This not only puts the inherent muscle memory knowledge of the front lines to work for customers—it also frees up what data science resources might be in place to tackle what is likely a backlog of projects.

Another assumption is that digitalization efforts have to start from ground zero. Existing data are all you need to begin a fruitful digitalization journey that will realize benefits in a relatively short time frame—especially when you add solutions like those provided by AspenTech to:

- Capitalize on and be used by those with process expertise you have in house

- Leverage existing data

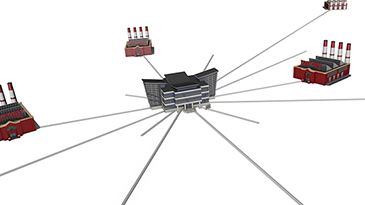

- Scale to enterprise level quickly to ensure that small issues can be found before they become big, rather than hunting for only the large interruptions

Many organizations have also spent much time and expense on data historians. This investment should not be wasted because existing data has a story to tell. Time-series data can be enabled and combined with other sources such as computer maintenance management system (CMMS) data to drive predictive applications and analytics. Digital technologies like asset monitoring tools can deliver the earliest, most accurate warning of equipment failures while prescribing detailed actions to mitigate or solve problems. Using machine learning, products such as Aspen Mtell® can recognize precise patterns in operating data that indicate degradation and impending failure—well before it happens—to provide a number of benefits:

- Prescriptive guidance

- Potential failure avoidance

- Low-touch machine learning

- Equipment- and process-agnostic

- Earlier detection of equipment wear

- More accurate failure detection with fewer false alarms

When you consider that predictive maintenance capabilities are expected to reduce unplanned shutdowns by up to 10 days, it behooves the power industry to invest in these solutions—sooner rather than later. Their enterprise-wide adoption ensures protection of critical assets and prediction of the “small” issues before they become big problems.

Clearly, as the industry moves more fully into the digital transformation age, asset monitoring is paramount. Among the APM technologies in the marketplace today, Aspen Mtell stands out for its distinct ability to provide earlier prediction of asset failures while reducing or eliminating false positives. Aspen Mtell was also recognized by the hydrocarbon processing industry in 2019 for its ability to identify leading indicators of asset failure and alert plant staff weeks prior to breakdown, allowing time to plan maintenance and reschedule production to minimize financial impact.

To learn more about predictive analysis and maintenance solutions, download the whitepaper Kickstarting Your Predictive Maintenance Journey with Existing Data and Resources: Insights for the Power Industry. For some additional reading, see Facilitating Predictive Maintenance of Electrical Assets with Pervasive Sensing Strategies and The World's First Autonomous Power Plant Would Be A Win For The Grid.

Leave A Comment