Many manufacturing and supply chain leaders are astounded when I share with them the customer success story about a leading specialty chemicals manufacturer that increased its total manufacturing site throughput by 20%, without incurring additional capital expenses. This improvement was achieved thanks to a digital production scheduling and real-time manufacturing collaboration workspace investment which had a two-month payback period. This customer has become more agile meeting their customers’ production requirements, even when those demands grow quickly and unexpectedly.

How common is a 20% production throughput improvement?

Like me, you may be wondering how common – or uncommon – is a 20% production throughput increase, thanks to improved production scheduling and collaboration? When chemicals customers present at our conferences and webinars, they typically report up to an already impressive 5% increase in manufacturing site throughput.

Well, I got quite excited in recent months when I learned about two new specialty chemicals success stories that also experienced 20%+ throughput gains, enabled by the Aspen Plant Scheduler™ and Aspen Schedule Explorer™ solutions! I set out to speak to all three customers to get their perspective on this crucial question:

“What prevented your site from realizing this step change in manufacturing and supply chain performance with your previous scheduling tool(s) or processes?”

Customer insights on throughput gains

All three specialty chemicals customers were doing some form of short-term planning/scheduling with some other tool(s) prior to converting to AspenTech’s solutions. In all three cases, they were relying on a combination of SAP ERP scheduling-related functionality (e.g. MD04, MMBE, CM25, PP/DS, etc.) and home-grown spreadsheets. When I probed deeper, I was able to pinpoint commonalities across the customers in terms of what had fundamentally changed in how they now schedule compared to the past.

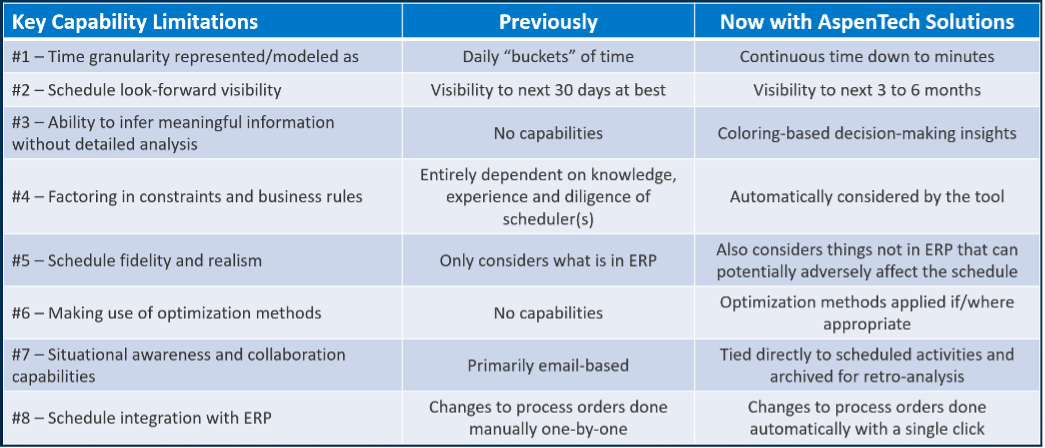

Figure 1: Capability limitations in customers’ previous scheduling tools that

prevented them from unlocking net new business value.

#1 – Schedules used to be limited to daily periods as the lowest level of time granularity and visibility.

These customers used to produce schedules in which the column headers represented daily time periods (e.g. day 1, day 2, etc.). Their schedules would contain values in cells beneath the time periods to represent quantities of materials to be produced that day. They had no visibility to hours and minutes within a day.

One customer explained that over the years, they had tried to increase the number of batches produced each day, but it hadn’t always gone well and could result in less batches being produced rather than more. For this reason, they scheduled what they thought was achievable based on experience using a “number of batches per day” approach. With AspenTech, their schedule is now in continuous time and has provided them with the granularity and accuracy needed to identify gaps of lost time and “squeeze” more activities in the time available and therefore increase production.

#2 – Schedules used to only provide 30 days (at best) look-forward visibility.

These customers previously didn’t look out for more than 30 days for many reasons. The key one: the longer the time horizon, the more columns in their spreadsheet tool and the more time/effort would be required to update the schedule to reflect inevitable daily supply/demand changes and knock-on effects across the time horizon.

One customer explained that there wasn’t enough time in a day for their scheduler to ensure that anything beyond a 30-day schedule would be effectively capacity constrained. This affected their sales team’s ability to effectively manage customer expectations with respect to order promise dates and quantities. With AspenTech solutions, their schedules now look out 180 days (in continuous time), while fully considering capacity constraints and production sequencing. The increased schedule visibility allows their customer service teams to help steer the order taking process further out to be more aligned with the optimal manufacturing schedule. Thus, simultaneously minimizing schedule break-ins while maximizing their on-time in-full (OTIF) KPI and increasing production throughput. They have been able to earn a higher degree of trust with their customers, as evidenced by a massive KPI step change in their latest net promoter score (NPS) customer survey, following project completion.

#3 – The schedulers were previously unable to infer meaningful information without detailed analysis.

All three customers previously had difficulty seeing and understanding all complications in their schedule, making it hard to uncover potential problems. Any given day, the schedulers need to make lots of decisions related to schedule changes and their upstream/downstream effects to various KPIs.

One customer was extremely enthusiastic about their ability with AspenTech solutions to visualize at-a-glance projected raw materials shortages, or batch lateness. By leveraging color-based decision-making insights, the scheduler can now see what can and cannot be pushed out on the schedule and answer in minutes questions that previously would take hours. This enables the scheduler to maintain accurate schedules, which allows their sales teams to commit to more volume and improve customer service.

#4 – Factoring in constraints and business rules used to be entirely dependent on the knowledge, experience and diligence of schedulers.

Scheduling is an extremely challenging and demanding job. A scheduler needs to learn or reference a large body of knowledge related to very specific rules or constraints related to the manufacturing process.

All customers shared stories about having to previously consult numerous spreadsheets or documents to review things like minimum/maximum batch sizes, contamination/cleaning matrix and factor them manually into their schedules. When the primary scheduler was away (on sick leave, on vacation, on weekends, etc.), the quality of the schedule would drop significantly. Now all the relevant business rules and constraints are automatically considered within the AspenTech solutions. It’s been saving tens of hours per month for all schedulers at these companies.

#5 – The schedules used to only consider information available in their ERP, limiting fidelity.

Generally, what is modelled in the ERP system is limited to what matters for product costing (e.g. equipment, work centers, routings, product versions, recipes, raw materials). There are many things not modelled in an ERP system that can potentially adversely affect the production schedule (e.g. packaging lines, pre-mix tanks, hot boxes, filters, pumps, shared labor, cooling systems, storage tanks, etc.).

One customer explained that they previously had bottlenecks they didn’t even know existed! Their operations team handles temperature sensitive materials with storage split between ambient, freezer and heated storage so they utilize hot boxes and freezers as part of their production process. There was no information in their SAP ERP system or anywhere else about these resources, all of which happen to be bottlenecks. Their schedules are now realistic thanks to AspenTech.

#6 – Not taking advantage of scheduling optimization methods if/where appropriate.

Some scheduling complexities are quite difficult, so schedulers employ “rules of thumb” to minimize time spent on them. Mathematical optimization methods can provide recommended schedules to a variety of scheduling complexities (e.g. campaigning/sequencing optimization, batch tank selection, blending, etc.).

One customer is now using optimization as their scheduling “co-pilot” to get recommendations on the best sequencing strategies (in continuous time) for bottleneck units. The optimization considers raw materials availability, customer demand quantities and dates, available capacities, inventory levels and sequence dependent transition times – across the entire schedule time horizon. In a matter of minutes, the system explores and evaluates millions of potential sequences and then presents recommendations to the scheduler, along with the proposed schedule’s performance KPIs. This is analogous to using GPS app to find the fastest route from location A to B.

#7 – Situation awareness capabilities were rudimentary and collaboration was email-based.

Situation awareness is a critical element of successful manufacturing execution. Inevitable daily supply and demand changes pose a variety of situation awareness challenges for manufacturing personnel, including potential for information overload, understanding information in the right context and ensuring the latest information is always available. Unfortunately, many manufacturing enterprises rely on rudimentary email-based communication to collaborate with respect to schedule visibility and execution status.

All three companies explained how Aspen Schedule Explorer has become one of the most vital systems to their site operations teams (e.g. production, logistics, planning, maintenance, R&D, etc.). One company stated that they had never witnessed a technology so easily (less than an hour of training), quickly and enthusiastically adopted (in less than a week) by their entire production team (who are apparently extremely resistant to change). People now have visibility to when batches started and if they started late compared to the schedule. Operations personnel now have visibility to any special instructions related to a cleaning before a specific production – and can collaborate in real-time to clarify any misunderstandings that would lead to costly mistakes.

#8 – ERP process orders updates used to be done manually one-by-one.

Whenever there are changes to a schedule, all impacted process orders in the ERP system must be updated with respect to any changes in quantities, dates and manufacturing resources. Schedule changes can have knock-on effects on many other scheduled activities which result in a tremendous number of changes to ERP process orders.

One customer explained that updating process orders in SAP ERP for changes to their previous 30-day schedule used to require 3-4 hours every week. It was all manual, so it required changing them tediously one-by-one, while focusing on not making typing mistakes. Now with the AspenTech system, all orders get automatically updated in SAP ERP with a single click across an expanded 180-day schedule horizon! The schedulers love this as you can imagine.

Closing thoughts

Increasing throughput is just one of many other production scheduling benefits. As I stated in another blog, Aspen Plant Scheduler and Aspen Scheduler Explorer are powerful “force factor multipliers” which typically deliver economic and operational benefits across numerous KPIs including:

- Increasing throughput and top line revenues.

- Decreasing variable manufacturing and shipping costs and bottom-line margins.

- Improving asset utilization and overall equipment effectiveness (OEE) KPIs.

- Enabling resilient cash flow via better inventory management and improved on-time shipping.

- Increasing customer service metrics KPIs and strengthening a manufacturers’ client reputation as being trustworthy, reliable, agile and proactive.

Make sure to prioritize investigating scheduling and manufacturing collaboration in your digital investment priorities. It may well be one of your biggest untapped opportunities!

.png?h=250&w=975&la=en&hash=BB8F1C20DE08F120AE7E800530C81B2E)

.png?h=415&w=675&la=en&hash=80A9DF1FB2D76515E80AF962D596BF50)

Leave A Comment