Carbon capture and storage (CCS) is one of three red hot investment areas in sustainability, along with energy efficiency and hydrogen economy, according to two surveys recently completed by Aspen Technology.

Until about five years ago, carbon capture was dismissed due to the inability of advocates and innovators to achieve the needed economic and technical breakthroughs. In AspenTech’s most recent sustainability survey, which polled 340 global companies, 65% of energy and chemical companies indicate they are already investing in or actively planning to invest in CCUS (carbon capture utilization and storage). What changed?

Carbon Capture Economics

One thing that’s changed is the basic economic calculus of carbon capture. With the value (as set by carbon taxes) of removing CO2 from emissions at roughly $75 per ton of CO2 capture and stored, projects are immediately attractive.

Also, innovations have chipped away at the “green penalty” for carbon capture. Process arrangements have become more efficient. New solvents have been invented. Better ways of extending life of solvents have been developed. Solids such as zeolites have entered the picture.

Real breakthroughs have also been made. Bill Gross, CEO of Heliogen and founder of Carbon Capture Inc, has combined breakthrough efficiencies in solar at Heliogen with new direct air capture concepts at Carbon Capture Inc, and applied AI technology from AspenTech (as reported by Bill Gross at OPTIMIZE 2019), to tie more closely together solar with direct air capture, improving the overall economics.

Of course, the other half of the picture is where are we going to store or utilize the captured CO2? A big part of the lifecycle cost of CO2 capture and storage will be identifying the right subsurface reservoirs to store the CO2, efficiently drilling and injecting the CO2, and monitoring it for the long term to make sure it stays in place.

The earliest CO2 capture projects that claimed positive economics, did so on the basis that the CO2 was used in enhanced oil recovery. Such projects have been performed effectively.

When CO2 is going to be stored in the subsurface for the long term, either in saline aquifers (where CO2 can be dissolved) or depleted oil and gas reservoirs, the efficiency of doing so becomes critical, since well drilling and well retrofitting becomes a high project cost component.

Digital Technology for CCUS

This is where digital technology and optimization have a huge and game-changing part to play.

Digital technologies are already being used on the capture side to optimize the design and operation of the capture systems. Technology Center Mongstad, a leading testing and innovation center for carbon capture, has built an integrated data collection and modeling system to understand the details of the performance of capture for each solvent and technology arrangement being tested and scaled up. They are now working with AspenTech to examine the use of the same models as operator training platforms for carbon capture systems. This use of technology for operator training and performance is crucial given the scale and speed of carbon capture systems envisioned in the world economy.

On the subsurface side, Kinder Morgan, a leading company engaged in injection of CO2 has been using The Subsurface Science and Engineering (SSE) integrated suite of geoscience software to efficiently validate future drilling locations and optimize the field performance; reducing planning costs significantly, managing CO2 injection and maximizing EOR yield.

As carbon capture and storage gains steam, look for leading companies to optimize both parts of the picture (capture and storage) together. At the feasibility stage, geophysical interpretation and reservoir modeling, help to effectively utilize all extant data and rapidly screen candidate subsurface reservoirs and aquifers for suitability and capacity. Then, at the funding stage, look for the simulation and economic modeling tools to rapidly optimize designs and technology selections to match the processing system with the target storage. Then, at the implementation stage, both of these tools can be optimized together, employing reduced order modeling and AI, to achieve the most secure and most effective execution plan. In the storage stage, geophysical interpretation and reservoir models will be able to monitor and provide visibility of the secure storage of the injected CO2 in the target reservoir.

In the longer term, during operation of the carbon management system, digital technology is even more crucial, to enable reliable, transparent and auditable records of the performance of the carbon capture storage assets.

Why CCUS?

The International Energy Agency (IEA) Energy Technology Perspective 2020 represents a commonly held viewpoint that CCUS will almost certainly play a key role in greenhouse gases (GHG) emission reduction and global energy transition. CCUS is already being retrofitted into existing power and industrial plants to tackle CO2 emissions and also provides a feasible pathway and support a rapid scaling up for low carbon “blue” hydrogen production. It is the most effective current approach for some of the challenging emissions in heavy industries (such as cement and steel production).

Beyond capturing carbon from industrial plants, Direct Air Carbon Capture is also being demonstrated as an approach to remove carbon from the atmosphere (“direct air capture”) in the current Climeworks/Carbfix Iceland project and the announced OXY carbon management program. This requires significant energy to drive air through the processing units in the volumes needed, but when very low-cost energy, such as from solar in the Carbon Capture Inc and Carbon Engineering approaches, is used, or when geothermal, as in the Icelandic case, is used, the cost penalty from energy consumption is reduced. Saudi Aramco, with easy access to land boasting the right solar profile and available depleted reservoirs, is reported to be a significant investor in Carbon Capture Inc, and one might imagine very low cost, high efficiency solar arrays in the Arabian desert driving direct air capture at favorable economics.

A continuing long-term solution?

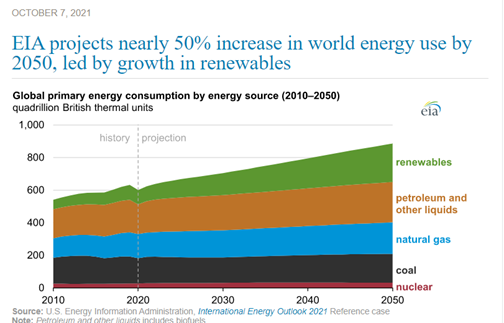

The US Energy Information Administration (EIA) projects that global demand for energy will increase 50% between now and 2050. This is partially due to a rise in the middle and upper class across developing economies, and also by global population increases. (see figure 1). Increased focus across all industries on energy efficiency can and will mitigate this curve somewhat, but the fundamental growth drivers remain. The increasing global demand for energy brings along with it increasing pressure on more effective and sustainable ways of delivering this energy to all consumers, from industry, to mobility, to domestic use. Shifts to renewables and associated increase in electrification is already an important trend.

While the world’s capability to deliver energy in the form of renewables grows dramatically, at the same time, forecasts by US EIA and organizations such as IEA and IHS CERA, fossil fuels continue to constitute a very significant energy source over the next forty years.

Given the reality of the continued role of fossil fuels for the next three decades, it is imperative to make rapid progress in scaling up the world’s capacity to execute carbon capture projects economically.

As Carbon Engineering CEO Steve Oldham said at ADIPEC 2022, “One plus minus one equals zero,” by which he means that since there are hard to decarbonize industries (such as steel) and the reality of the energy supply/demand curves through 2050, removing carbon directly from air (the minus one) can be a crucial part of the solution if the economics work.

Digital technology – such as the design, modeling, optimization, and data and monitoring solutions that AspenTech provides and continues innovating – are an important element of driving CO2 innovation and economics further.

Leave A Comment