The AspenTech Engineering Development and Product Management teams have been working hard to support cloud deployment and incorporate cloud technology since the development of aspenONE® V10. With recent releases, we have taken advantage of the scalability of the cloud in enhancing our solutions. Now, working with customers, we are seeing that work come to fruition as customers deploy aspenONE® V12 Performance Engineering on Microsoft’s Azure Virtual Desktop (AVD). Customer adoption of Performance Engineering on AVD is being driven by the capabilities of AVD to seamlessly integrate with our customers corporate networks, the advantages to installation and maintenance in having a single install, and the new features in V12 that take advantage of the dynamic compute power available in the cloud.

Our customers are seeing the rapid convergence of Operational Technology (OT) and Information Technology (IT) which is giving leaders in the process industries the necessary agility to address the dual challenge of achieving operational excellence and sustainable performance. A key enabler of their success is the deployment of critical software via the cloud, enhancing scalability and flexibility by integrating modelers and data sources across the enterprise to unlock previously siloed insights.

Performance Engineering and Additional AspenTech Solutions Available on Azure

To support our customers in this journey to meet the dual challenge, we are pleased to make many of AspenTech’s industry-leading asset optimization solutions available for deployment in the Azure environment. Today, we focus on the company’s performance engineering solutions deployed on AVD, which simplifies integration of monitored process variables delivering a deeper understanding of your process so that you can make better operational decisions.

Hosting the performance engineering solutions on AVD simplifies the scalability and flexibility of the deployment while providing access to scalable cloud infrastructure and high-performance computing (HPC) to take advantage of features added to V12.

Process simulation and optimization technology has traditionally lived on the desktop. This has led to myriad limitations, from disparate versions being used within the same organization to both models and data being trapped in local environments. Deploying the AspenTech Performance Engineering Suite—which includes the award-winning Aspen HYSYS® and Aspen Plus® simulation software with leading economic evaluation, equipment design and layout tools—onto a cloud environment like Azure provides capabilities in the enterprise to meet today’s dual challenge.

Customers deploying the industry’s leading process simulation and optimization software on AVD provides a simple cloud deployment of the full featured software. AVD enables customers to have a single centralized image for their deployment, reducing overall company installation effort and speeding adoption of new functionality and performance.

Benefits of Deployment on AVD

Deployment on AVD provides easy access to HPC enabling faster development of models for complex processes by evaluating thousands of operating conditions simultaneously. Additional benefits include:

- Consistent deployment across the enterprise. Instantaneous access to latest software while reducing IT costs

- Improved productivity and collaboration by making models and data accessible anytime, anywhere on Azure. Optimum performance across multiple variables and collaboration across roles

- Integrated workflows allowing for cross-functional collaboration from design to operations, reducing design time by 50%

- Easy and scalable way to deploy Industrial AI and digital twins

Democratizing Analytics Through Industrial AI

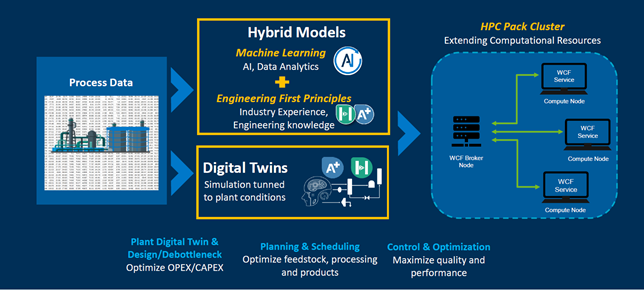

Industrial AI expands the scope of process challenges addressed by simulation and optimization software by simplifying the incorporation of plant data into first principles-based flowsheets. Machine learning (ML) techniques combined with engineering constraints allow process models to be tuned with real-time process data, or high-performing models to be built for previously impractical simulations.

Centralized deployment on AVD vs. the typical desktop deployment provides companies with a reason to reassess their model and data storage practices to enable their users to access data from across the enterprise to tune or build models. The sharing of data helps users build on previous work and company knowledge to be able to build powerful AI models based on analytics. The AI models created are simplified representations of the process that can then be deployed in planning and production optimization tools instead of being locked in the domain of the process modeler.

Industrial AI combines AI/ML techniques with engineering fundamentals and domain expertise. aspenONE V12 includes Aspen Hybrid Models™, which are created using an AspenTech-hosted SaaS service, combining historical plant or simulation data with first principal models. The resultant models can more accurately simulate the equipment in the plant and in some cases allows for process that were not able to be accurately modeled by first principals to now be included in your simulation.

Storing your historical plant data or range of simulation data created by Aspen Multi-Case™ in your Azure Tenet along with Aspen Performance Engineering creates an ecosystem simplifying the data transfer to create and deploy your Aspen Hybrid Models. Aspen Multi-Case easily runs thousands of simulation cases concurrently allowing a more complete analysis so results can be used to navigate operational complexity and make more accurate decisions, faster.

Aspen Multi-Case can produce necessary data to feed reduced order hybrid-model creation or the data can be combined with limited plant data to produce a first principles driven hybrid model.

Aspen Performance Engineering in the Cloud Supports New Workflows

Rapidly Deploy Reliable Digital Twins

Using the AspenTech Performance Engineering Solution on AVD also allows customers to remotely and securely deploy multiple real-time digital twins as needed to improve plant operations and track sustainability goals. Digital Twins combine models and data to create virtual representations of physical assets. Digital Twins enable enterprise-wide insights to control what otherwise can’t be measured by providing precise KPI tracking, equipment monitoring and process improvement while ensuring safe operations and increasing margins by 5-10%. KPI tracking can be used to adjust operations quickly due to changing market conditions, sustainability and energy reduction goals, or to help maintain productivity as workforce demographics shift. In the end, this helps to accelerate digitalization through quick deployment of multiple digital twins.

Given the tactical and strategic advantages now available by deploying V12 performance engineering solutions to AVD, we are currently working with many customers to assist them in moving to Azure. We encourage existing AspenTech customers to work with your account team to review your V12 deployment options and consider Azure.

Watch the “Streamline Your Upgrade to aspenONE® V12 with Microsoft Azure” on-demand webinar to learn more.

Leave A Comment