Activated Analysis in Aspen HYSYS® and Aspen Plus®

Optimize your design by evaluating process alternatives analyzing their cost, energy usage, emissions and equipment design from the same environment.

Reduce Engineering Time and Cost with Simultaneous Multi-Disciplinary Analysis

Economic Analysis

Analyze the economic impact of any design changes in the simulation, and screen design option and process configurations.

Energy Analysis

Maximize energy savings and minimize utility usage with design recommendations developed using built-in pinch analysis.

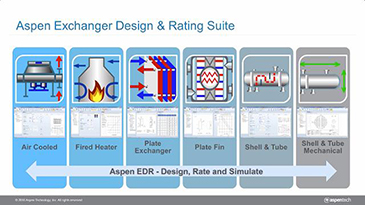

Heat Exchanger Design and Rating

Fully incorporate heat exchanger designs within the simulation to produce the most optimal designs at the right economics.

Emissions Dashboard

Reduce the carbon footprint of your design by analyzing the impact of any design change on your emissions and carbon tax numbers.