Prevent Unplanned Downtime with Prescriptive Maintenance

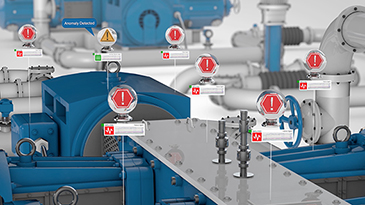

With current shortages in on-site staffing, many companies struggle to prevent unexpected breakdowns. AI and machine learning technology leverage precise pattern recognition from manufacturing assets to provide weeks, or even months, of advanced warning on imminent degradation and failures.

In this on-demand webinar, AspenTech’s Mike Brooks provides insights into how you can:

- Prevent equipment breakdowns by adjusting the process, eliminating damage-causing behavior

- Plan safe and environmentally incident-free service and repair

- Improve asset availability with contemporary maintenance practices

Learn how leading companies are using asset performance management to increase equipment availability and prevent unplanned downtime across the production system.