Sardeolica Digitalizes Wind Farm Maintenance - Reducing Costs, Improving Uptime and Transforming Culture

In this case study, discover how Sardeolica used prescriptive maintenance to achieve maximum value and expects to reduce maintenance costs up to 10 percent per year.

Sardeolica launched its digitization process with the aim to optimize plant control, plan maintenance interventions during low-wind periods, increase productivity and mechanical availability with a view to continuous improvement and implement a digital maintenance culture.

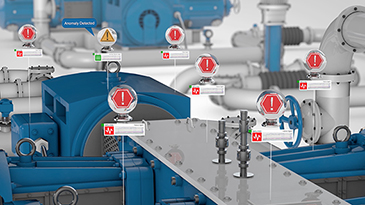

They installed a network of vibration sensors and equipment data collectors across the wind turbine generators and gear boxes—a key step in applying digitalization to their wind farm operations. This allowed the company to transform its maintenance function and more proactively manage wind assets to not just avoid catastrophic damage, but also potentially extend their lifetime.

Learn more about how this collaborative project with AspenTech® exceeded the expectations of both organizations.