Using real assets to evaluate a potential opportunity can be cost-prohibitive — and even dangerous. As an example, the airline industry long ago determined that simulators were a much safer and more cost-effective means to train and test strategies and performance.

Why should the process industries be any different? Why are we still settling for suboptimal workarounds, firefighting, reactive decision-making and the inability to consider all relevant options?

Technology is now available to help change the speed and quality of decision-making. Risk is much easier to test in a “digital twin” than in the real facility. The industry must embrace the means to predict equipment failure and respond with the safest, most profitable and most sustainable mitigation options.

Using Aspen Fidelis Reliability™ as a decision model, we can rapidly combine information from other digital sources — such as machine learning, predictive analytics, multivariate analysis, real-time optimization, planning and scheduling and alarms from data historians — to understand risk and profit and make informed decisions.

To illustrate the possibilities this presents, let’s examine the workflow between Aspen Fidelis Reliability and the predictive analytics of Aspen Mtell®.

The Workflow

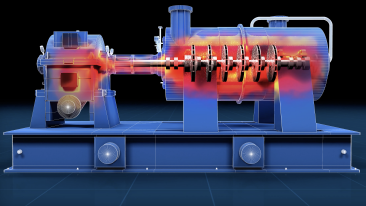

Using machine learning, Aspen Mtell can predict when a failure is going to occur. For this example, the customer received an alert that a compressor has a high probability of failure in the next 14-21 days. This information is invaluable by itself, but wouldn’t it be even more effective if your operators knew exactly which action to take to safely minimize downtime and revenue loss? This is where Fidelis is deployed as a digital twin!

Using a system approach to modeling, Fidelis takes into account the impacts from design redundancy, capacity sizing, pipe flows, operating logic, maintenance approach, logistics alternative, market demands and even weather. After creating a Fidelis digital model of the asset and process, evaluating the impact of this pending failure becomes quick and easy. Depending on the process, Fidelis can automatically run several likely cases.

For example, we can evaluate the revenue impact of:

-

Doing nothing — that is, letting the equipment run to failure

-

Ordering the necessary spare parts ahead of time to reduce the overall downtime

-

Lining up a spare compression skid (requiring a small amount of downtime to switch the main process over to the installed spare)

-

Increasing run rates for a short period of time to build up buffer volume (allowing the downstream process to run longer during the outage)

For another operation, perhaps changing the way you operate or changing the crude/product slate would be potential alternatives. Regardless of the options, Fidelis can quantify the production impacts of each. Using retained revenue as the key performance indicator (essentially ROI), making these difficult decisions becomes quick and easy.

Get the Full Picture to Make the Best Decisions

Combining Aspen Fidelis Reliability and Aspen Mtell together, we can now go from reactive decision-making to preplanned action. In addition, Fidelis provides a means to quantify each of the relevant options to minimize lost production and revenue.

Fidelis can also be used to help with ongoing strategic decisions around debottlenecking and major capital projects. Aspen Fidelis Reliability is a system approach to reliability — it allows you to quantify the true value of any improvement project, maintenance change, operations improvement or supply chain constraint.

Additionally, Fidelis will give you an accurate, comprehensive bad-actor list, quantified by lost revenue and production — not just by maintenance. You can more effectively perform lifecycle analyses on assets, including asset utilization, overall equipment effectiveness and other parameters that define operating conditions, reliability and costs of assets.

With Aspen Fidelis Reliability, decision-makers can maximize the economics of business decisions by going beyond the equipment level and accurately predicting future asset performance of the whole system.

To learn more about how Fidelis can help with your decision agility, please check out this video.

Leave A Comment