In November, a number of key experts in refinery planning and advanced control gathered at a one-day forum hosted by AspenTech in Houston.

The discussion focused on AspenTech’s vision for unified production optimization in refining and chemicals, and how some leading refinery organizations are forging ahead in this area. AspenTech VP of Energy Sales Bill Hendricks and I challenged the audience to aim higher — to aim for a goal of increasing refining margins by $8 a barrel (in a world of $50 per barrel oil), not just by $0.50 or $1, as many organizations are satisfied to do.

As came out during the day-long forum, and during the networking breaks, the road to achieving these goals is through a combination of:

-

Existing, foundational plant modeling and optimization tools

-

New and rapidly advancing AI and machine learning technologies

-

Organizational thinking and style changes which will enable these technologies to have accelerated impact in the conservative refining and bulk chemicals industries

Unified production optimization is a key building block for digital transformation in refining and olefins, the experts gathered together agreed. AspenTech VP of Manufacturing Solutions Steve Williams explained his team’s innovation direction in making unified production optimization a reality. He noted that a recent Accenture digitalization study showed that adoption of multivariate advanced process control (APC) on key refinery units is the biggest success case today for digital transformation, according to the refining organizations surveyed.

What AspenTech has done, through the leadership of Steve and patent-holder Michael Harmse, is take advanced control forward into an arena termed “Adaptive Process Control,” in which the control software is transformed to become self-healing and self-improving. This third-generation advanced control is branded “DMC3” by AspenTech.

But beyond that, AspenTech is moving aggressively to fill the automation gap between plant planning and scheduling and advanced control. This is a particularly exciting area because it offers the promise of a closed-loop autonomous solution to dynamically controlling production to meet refinery planning targets.

ExxonMobil’s David Hokanson, in an on-stage interview with AspenTech’s Alex Kalafatis, gave a strong and compelling narrative around the breakthroughs that are possible through evolving to the Aspen DMC3™ adaptive process control platform. The concept that Aspen DMC3 represents, namely self-healing technology, is tabbed by Gartner as one of the top eight technology trends in industry in 2019. David talked about the dramatic step-change that the technology has made for ExxonMobil, enabling him and his team to roll out multivariate control on many more units, in more global locations on a highly accelerated timetable.

There were a lot of questions from the audience, and David’s narrative was compelling to the advanced control experts present. He shared a number of ideas as to how ExxonMobil has been able to embed a more agile and accelerated technology adoption approach within a large global organization.

Capturing Margin Value Through Dynamic Optimization

Another exciting presentation was given by two Chevron leaders, who are driving dynamic optimization technology within their refining sites. They described the implementation of the GDOT dynamic optimization system in the Chevron El Segundo refinery. The GDOT software technology (which was recently acquired by AspenTech in the acquisition of APEX Technology) has enabled Chevron to capture very significant ongoing margin value through setting more aggressive planning targets and achieving them on a monthly basis.

Chevron showed concrete before and after production data, demonstrating the significant improvement in yields achieved through the dynamic optimization system. The system’s developer, Henrik Terndrup, explained how GDOT is able to fill the crucial gap between planning and advanced control, automating that bridge and incorporating minute-by-minute feedback from plant operations and consequently enabling dynamic adjustment of advance control setpoints.

Perhaps, though, the most illuminating aspect of Chevron’s approach came out in an on stage conversation between Henrik and process control engineer James Gunderman. They discussed the manner in which Chevron has reorganized how the refinery staff work, putting together planners, APC engineers, operators and an optimization lead to create collaborative multi-functional teams to take maximum advantage of what the breakthrough GDOT technology enables.

Moreover, this forum, and several similar ones we’ve hosted, have uniquely brought together planners and advanced control experts in one conversation. This was remarked on by the attendees as being extremely valuable. We’ve had similar feedback from our recent Digital Refining Transformation seminars this fall held in Kuala Lumpur, Malaysia, Rayong, Thailand and Mumbai, India.

Want a similar experience? We have upcoming refining transformation seminars with similar agendas coming up in:

-

Amsterdam (24 January)

-

Jakarta (30 January)

-

Abu Dhabi (11 February)

-

Doha Qatar (13 February)

-

Korea (late February)

We’d love to see you at one of these events. Please contact me for registration information.

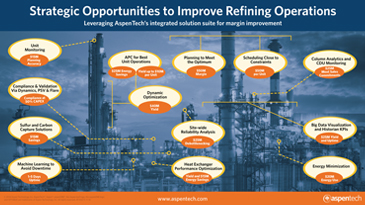

For more information on applying digital solutions in your refinery, you can read our recent downstream white paper or view our refining operations infographic.

Leave A Comment