AspenTech and our Implementation Services Providers (ISPs) are helping customers on their supply chain digital transformation journeys. This month, I had a conversation with Aris Televantos, Founder and Director of Delevant Business Solutions Ltd., an AspenTech supply chain ISP, to get his perspective and insights on how COVID-19 has accelerated the adoption of supply chain planning, scheduling and optimization capabilities in the Lubricant Base Oils, Oil Refining, and Petrochemicals industries.

AspenTech and our Implementation Services Providers (ISPs) are helping customers on their supply chain digital transformation journeys. This month, I had a conversation with Aris Televantos, Founder and Director of Delevant Business Solutions Ltd., an AspenTech supply chain ISP, to get his perspective and insights on how COVID-19 has accelerated the adoption of supply chain planning, scheduling and optimization capabilities in the Lubricant Base Oils, Oil Refining, and Petrochemicals industries.

Roch Gauthier (RG): Hello and welcome Aris. If you could, please share a bit about yourself and Delevant and your team’s experience in delivering Aspen Supply Chain Management (SCM) forecasting, planning, scheduling and optimization solutions.

Aris Televantos (AT): Hi Roch and thank you for the invitation. I have been involved in the field of supply chain management for my entire professional career. I studied Operations Research at Stanford University, got my first job at i2 Technologies in 1997, and then in 2000 I switched to Aspen SCM. I have been delivering projects in all areas of Aspen’s SCM solution stack ever since, including integration with leading ERPs.

In 2008, I founded Delevant in Nicosia, Cyprus. Today, Delevant’s growing team of supply chain consultants are delivering and supporting Aspen SCM and related business intelligence solutions across many industries including petroleum refining, lubricant base oils, petrochemicals, and specialty chemicals. Our location in southeastern Europe enables us to serve customers in many regions including Europe, Middle East, Africa, the Americas, and east Asia.

RG: In the past 2 years, supply chains have been tested like never before. What are some insights on how Delevant has been helping customers improve their supply chain forecasting, planning and scheduling capabilities across different industries; let’s start with the Lubricant Base Oils industry.

AT: Yes, of course. Delevant recently helped two lubricant base oil companies: ILBOC in Spain, and another company based out of the Middle East. Lubricant base oils planners and schedulers focus on keeping critical units running continuously because they are expensive to stop. The challenging part is making the best decisions on how to adjust the reactor production rate and modes of operation to keep the numerous inventories stored in a multitude of tanks within their limits, whilst considering what you will be shipping via different transportation modes such as ships, pipelines, and trucks. Managing this process manually using spreadsheets is quite difficult, time consuming and requires significant subject matter expertise.

The Aspen Plant Scheduler-EO TM solution we delivered has helped these clients to standardize their work processes so that they can be done quickly and effectively by more junior employees. Leveraging optimization, these clients were able to react to the COVID-19 challenges, optimize their shutdowns, and determine the campaign optimal run rates and transitions of each feed to maximize profitability for the next 18 months. Most importantly, they can rerun optimization as needed to incorporate the daily inevitable supply and demand disruptions and produce daily schedules for the next 120 days. Their sales and marketing teams are making use of future inventories projections and granular visibility to improve their selling activities: adjusting demands to match supply, arranging ship vessel schedules, as well as evaluating spot sales opportunities.

Delevant is extremely proud of the statement made by ILBOC’s planning manager at a recent AspenTech customer roundtable panel discussion: “the solution allows to manage supply and demand variations with a fast response and achieve perfect control spanning the shorter-term execution time horizon into the longer-term planning horizon.”

|

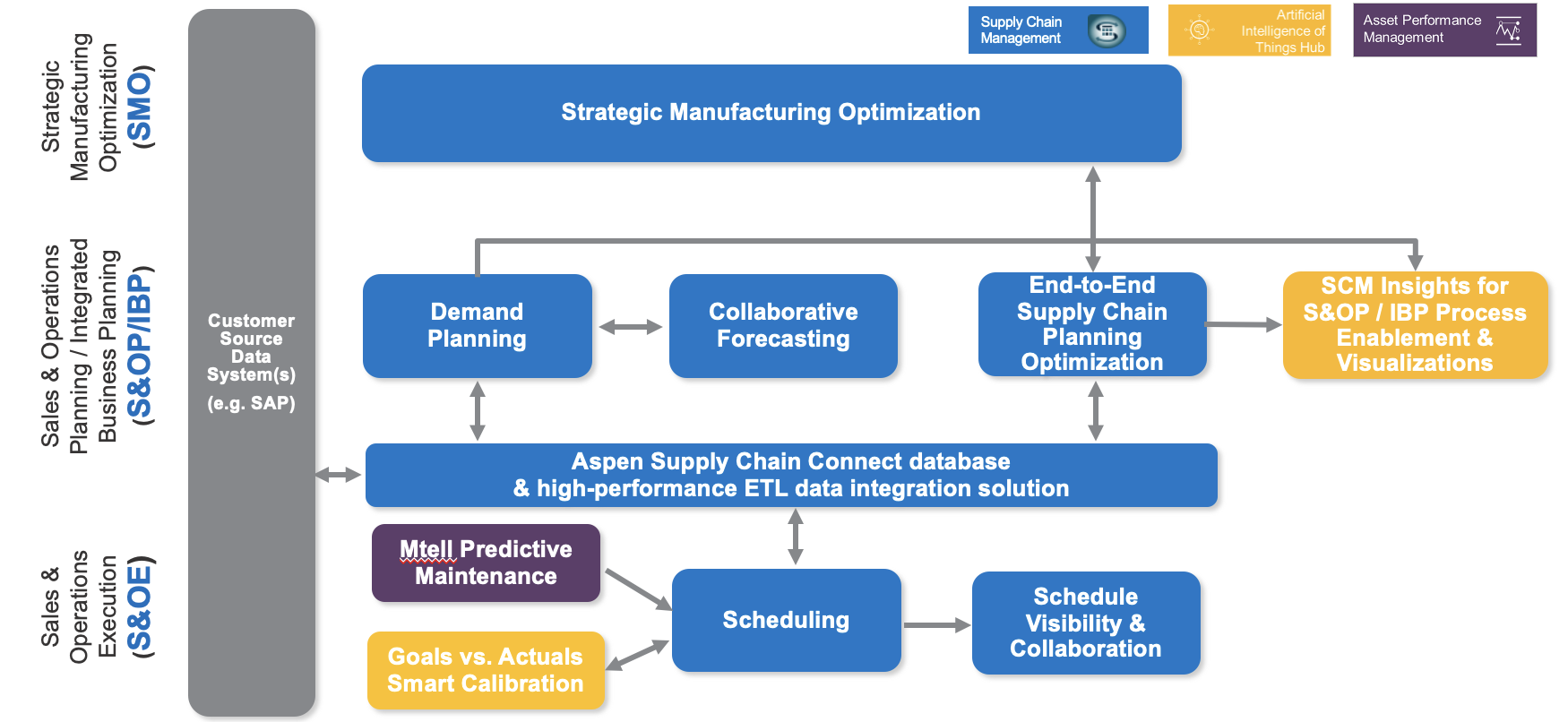

| Figure 1: Overview of aspenONE® SCM solutions and synergies with other AspenTech suites |

RG: Let’s move on to the petrochemicals industry. Can you please share some of the challenges faced recently by petrochemicals companies and how Delevant is helping solve them?

AT: There has been an incredible amount of volatility and uncertainty in the past 2 years across all industries. This is especially true in the petrochemicals industry. I have witnessed the usage of supply chain scenario analysis rise to a level that I have never seen before.

At the beginning of the pandemic, “what if” supply chain scenario analysis was primarily used for business contingency planning purposes. Clients were looking to understand the financial and operational implications of key production sites becoming unavailable due to COVID-19 outbreaks and associated lockdowns.

More recently, scenarios analysis is being used to help companies plan for when they may recover from, and exit, the pandemic and go back to more steady state operations. Other types of recent “what if” scenario analyses have been related to geo-political circumstances that affected raw materials supply, as well as local labor strikes which impacted production or logistics capabilities and created inventory problems.

Delevant has helped an integrated petrochemicals client to run and evaluate holistic end-to-end supply chain scenarios for their many basic and derivative petrochemicals finished products. The Aspen Supply Chain PlannerTM solution, working together with Aspen Collaborative Demand Manager and Aspen PIMS-AO, provide this client with the full economic and customer service driven tradeoffs during optimization – for any “what if” scenario evaluated. All these results are presented in a business intelligence dashboard for analysis and decision making, which is highly appreciated by the client’s business leaders and supply chain planners.

RG: Let’s wrap up the conversation by talking about the oil refining industry. Can you share some highlights of an on-going Aspen SCM implementation that Delevant is doing in this industry?

AT: A client we are working with is a fuel oil company with operations in South Africa. One of their current supply chain challenges is to better forecast demands for their products in various markets as they come out of the pandemic and into more complex geopolitical events that have greatly affected oil prices. This has related implications to establishing and negotiating annual contracts with some of their key partners and keeping track of these moving forward.

Delevant is implementing the Aspen Collaborative Demand ManagerTM solution for this client, in collaboration with a large global systems integrator. The solution will help this client manage their end-to-end demand management and collaborative forecasting process in conjunction with powerful forecasting algorithms.

RG: Thank you Aris for sharing some valuable insights with our audience. If someone wants to connect with you, what’s the best way to get in touch?

AT: People can get in touch with me via LinkedIn, at www.delevant.com or directly at aris.televantos@delevant.com

Learn more about and how AspenTech can help your organization increase supply chain agility to better manage uncertainty and volatility.

.png?h=250&w=975&la=ru&hash=72FC63A46A823565CDC7A1565D5933A6)

Leave A Comment