Plan & Schedule

Reach New Heights: Six Best Practices in Planning and Scheduling

Learn the six best practices in planning and scheduling that will enable plants to advance their technological maturity—making your plant more reliable and profitable.

White Paper

Keeping your Refinery Right on Schedule

Learn how an advanced scheduling solution can help ensure your refinery stays right on schedule while gaining a competitive advantage in the market.

Executive Brief

Leading Refiner Reduces Planning Run Times from Hours to Minutes and Finds Profitable Solutions

Learn how this world leader in refining reduced planning runtime from 30 hours to 90 minutes, making the process 95% faster and allowing them to respond to market changes much faster.

Case StudyControl & Optimize

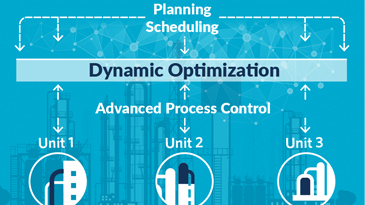

Infographic: Unified Production Optimization Architecture

With vertically integrated unified production optimization, you can dynamically optimize multiple process units in closed loop.

Infographic

Next Generation of APC Delivers Benefits for Ethylene Manufacturer

Learn how Qenos, an Austrailian ethylene manufacturer, used Aspen DMC3 to revamp a demethaniser controller with very limited resources and achieved a 5-10% increase in cold end throughput, a 40% reduc...

Case Study

Aspen GDOT™ for Refining

Close the gap between planning and actual operations with Aspen Generic Dynamic Optimization Technology (GDOT). Aspen GDOT™ aligns planning and scheduling objectives by dynamically optimizing and coor...

BrochureInsights & Execution

Aspen Enterprise Insights

Aspen Enterprise Insights is a unique hybrid-cloud-based software product with a flexible enterprise visualization and workflow management solution that delivers real-time decision support across your...

Brochure

Protect Profits and Prevent Margin Loss in Downstream

With downstream margins globally close to a 10-year low, according to S&P Global Platts Analytics and ExxonMobil, companies need to find new areas for improvement. Current digital solutions offer ways...

White Paper

Harness Big Data and New Analytics Technologies to Improve Manufacturing Competitiveness

Process manufacturers are besieged with all kinds of data. The increasing volume and detail of information captured by enterprises is a strong indication that leaders in every sector must deal with th...

On-Demand WebinarState of the Plant

Learn How Aspen HYSYS® Offers Refiners Streamlined Workflows to Update Refinery Planning

It’s critical to make sure your refinery planning models are in sync with changes in operating conditions or catalysts. However, the extensive effort required to update planning models means that many...

On-Demand Webinar

Borealis Achieves Faster Run Times and Better Quality Planning Solutions with Aspen PIMS-AO™

Learn how Borealis, a leading provider of innovative solutions in the fields of polyolefins, base chemicals and fertilizers, implemented Aspen PIMS-AO to support the optimization team and bring about ...

Case Study

Prescriptive Maintenance Software Helps Saras Improve Business Performance and Drive Operational Excellence

As part of an effort to drive reliability in its refinery operations, Saras turned to Aspen Mtell® prescriptive maintenance to improve equipment uptime and decrease maintenance costs.

Case Study