How a Multinational Biopharma Used PAT to Shift from Batch to Continuous Manufacturing

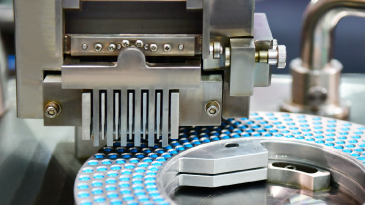

When Ferring Pharmaceuticals wanted to move from batch to continuous manufacturing, they found that laboratory assays were too time consuming to provide meaningful feedback for real-time control, and 100% product quality inspection was not possible.

In this on-demand webinar, learn how Ferring implemented Process Analytical Technology (PAT) to provide real-time process control enabling them to:

- Use spectral data pretreatment and multivariate modeling to ensure accurate and reproducible prediction of CQAs in real-time, eliminating laborious laboratory testing

- Obtain real-time feedback on quality deviations for closed-loop control to automatically adjust API dosing rate and regulate CQAs

- Leverage online measurement to allow 100% product quality inspection and real-time release testing, a key enabler for continuous manufacturing

Discover how Ferring used state-of-the-art PAT to enable the shift from batch to continuous manufacturing, which boosts production efficiency and consistency.