The world is much smaller today than in years past. Any product can be produced in many locations and delivered anywhere. Consequently, world-wide competition forces lower margins on process industries and they respond by seeking lower costs and greater productivity. The manufacturing processes become more complex and volatile, suffering greater uncertainty and ambiguity from any changes or deviations along a total product supply chain. We call this a VUCA (volatile, uncertain, complex and ambiguous) marketplace. Under such circumstances, manufacturers must understand any impending disruptions and act quickly to seize business opportunities and minimize safety, environmental, and profit risks. Response speed is key: technology prowess becomes an absolute necessity.

The technologies in digitalization, IIoT and Industry/Industrie 4.0 are promoted as essential to provide the platform upon which businesses may respond. What does that mean? That approach is broad and deep, so what is the essential first step?

Eliminate Unplanned Downtime

A 2016 study by the American National Association of Manufacturers (NAM) emphasized that global manufacturing industries suffer unplanned downtime that causes world-wide losses of $1.4 trillion USD or more each year. Stopping machines from breaking eliminates the most significant cause of margin losses and should be the number one target for all manufacturers executing digital transformation.

In the same year as the groundbreaking report, in October 2016, AspenTech acquired Mtell to capitalize on artificial intelligence (AI) technology and to bolster its strategy to master and lead asset optimization through cradle to grave – the total digital lifecycle.

Founded in 2006, Mtell had achieved significant breakthroughs in creating an application to monitor all types of equipment, understand the warning signs of degradation and provide extremely early alerts of impending breakdowns. Besides far earlier and more accurate alerts, which rendered breakdown avoidable, manufacturers benefitted from a novel methodology geared towards current manufacturing workers’ skills and experience. This methodology does not ask workers to be deep experts in engineering, thermodynamics or data science. They can still do state-of-the-art implementations because the technology is all there, but masked by a simple, familiar user interface. The Mtell team imitated how the iPhone embeds deep technology under a simple user interface allowing everyone to easily and quickly benefit from smart devices. Underneath the Aspen Mtell™ methodology, the AI-based software does the heavy lifting using analytics and machine learning.

Put AI to Work

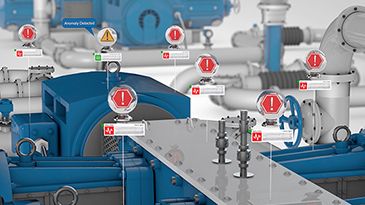

The Aspen Mtell methodology develops Autonomous Agents that execute every few minutes and do the work so that people do not need to analyze data. Agents are digital twins that learn normal and degradation behaviors and keep watching and warning.

Agents process real-time data across time and multiple dimensions, combined with asset management system data. Failure Agents can alert on root causes of degradation and provide prescriptive guidance on exactly when to service and repair or how to adjust the process to avoid the damage altogether.

Anomaly Agents learn the precise patterns that declare normal behavior and alert when there’s a deviation. The deviation could be a signature of degradation or a normal change in process behavior. The Anomaly Agent reacts by embedding the new pattern of normal behavior so that no false alarms ever happen. Additionally, Agents can work on any asset in any industry for any failure mode. When you have developed an Agent – it’s simple, you can do it yourself in a couple of hours – you can simply add it to all the equipment of the same type making it quick and easy to scale, for example, to give all the boiler feedwater pumps the same safety and breakdown protection.

The key benefits of the Aspen Mtell application are:

- Early stage alerts ensure early planning minimizes maintenance time and cost

- Reduced downtime with minimal impact on net product output

- Easy, quick to build, deploy, scale, and sustain

- Guards against process-induced damage to equipment

- Predicts when and what maintenance is required without needing to inspect

In today’s VUCA environment, Aspen Mtell is a necessity to understand equipment issues and react quickly. This award-winning software addresses skills shortages and ensures the most effective asset management to achieve stability and efficiency in plant operations and maintenance. Every minute you wait is exposing you to unnecessary risks and costs. There’s no time to lose - contact AspenTech today. For more information, read our latest white paper, "Prescriptive Maintenance: Transforming Asset Performance Management."

Leave A Comment