Early adopters of technology tend to look outside their own industries for ideas and better ways to do things. Examining how organizations in other disciplines have solved similar problems can provide inspiration. For example, engineers at Woodside Petroleum in Perth, Australia shared a video of a robot they created to explore remote locations and soon found themselves collaborating with NASA. An article in The Sydney Morning Herald called out the partnership as an example of how Western Australian energy and mining organizations are developing technology to cut costs and increase efficiency.

Drawing on the technologies that allow astronauts to collect mineral samples in space makes sense for mining companies looking to safely explore new areas that put human workers at risk. Adapting tools that have been used for similar purposes in different industries saves time and provides opportunities to innovate — and leading technology companies are eager to help companies see how they can leverage existing solutions for new use cases.

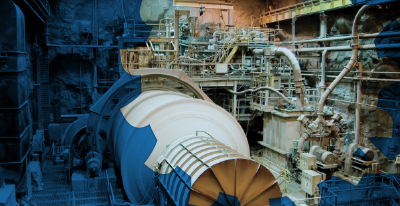

Miners are taking advantage of the latest technologies in AI and machine learning, IT/OT infrastructure and communications (Wi-Fi, 5G, LoRa) – tools that were previously not feasible due to high costs and limited access in remote environments. These technologies provide the foundation for additional initiatives, such as autonomous mining equipment, remote equipment monitoring, resource and geology modeling software and proximity detection systems to operate safer, greener, longer and faster. Many of the world’s advanced mines are currently using autonomous haul trucks, which have delivered great value during the 2020 pandemic as companies take steps to protect their workers by reducing the number of people on site.

Advanced Process Control, Asset Performance Management and More

Looking to leading technology companies to see how they have solved similar problems in industries with related concerns presents an opportunity for miners. For example, petroleum refiners have long used advanced process control (APC) to increase production and improve profits in upstream processes. Consultants from AspenTech partner BluESP saw that Glencore’s Mount Isa Mine in Queensland, Australia could use APC to optimize zinc recovery. With Aspen DMCplus® controlling a zinc flotation circuit, the mine reduced its use of reagents while maintaining grade constraints and realized cost benefits of over $1M AUD annually.

Consultants from AspenTech partner Greenfern Dynamics also helped South32 Worsley Alumina in Western Australia use general dynamic optimization technology (GDOT) to improve the management of plant volume and increase production targets with a payback period of less than four months.

In the same vein, asset performance management (APM) solutions providing predictive maintenance for manufacturing and petrochemical companies can clearly perform the same function for mining equipment with similar components, such as:

- crushers

- conveyors

- mills

- pumps

With insight into asset health and advance warnings of pending equipment failures, mines can avoid costly unplanned shutdowns. Machine learning helps identify precise failure patterns, allowing mines to more accurately predict – and avoid – breakdowns.

Increasingly, mines are in a position to capitalize on Industrial AI technologies. With AI built into applications that have long helped process- and asset-intensive industries operate more safely, profitably and sustainably, mines can easily take advantage of these solutions to improve their own operations. The vision is for mines to achieve semi-autonomous and autonomous operations, akin to the Self-Optimizing Plant. So, watch this space….

Quickly Capturing Value

The tide is turning. The refrain "this is the way we have always done it" is being replaced with the mantra "fail fast, learn faster." Mines can skip the “fail” portion of the equation by adopting digital twin technologies that have proven themselves in other industries – particularly those that deliver quick return on investment, such as APM solutions. Fast proof of value of becoming more critical for miners than ever before. In an article in the Financial Times, BHP CEO Mike Henry said that if the company can’t show the value of a technology investment within six months, the organization isn’t willing to try it.

AspenTech APM solutions that can be deployed within weeks – even remotely, which was unheard of a short time ago – deliver the type of fast returns mines need in a volatile market. Shortening the learning curve with tools that have delivered value in similar industries offers a fast track to success.

Learn more in the white paper "Maximize Mining Equipment Effectiveness, Minimize Margin Loss." Or join us for an upcoming event.

Leave A Comment