In my previous blog, I took a high-level view of the ways APM can support corporate goals for sustainability, among other things. In today’s blog, I get down to the nitty-gritty and review the APM Portfolio applications: AspenMtellR, AspenFidelisTM and AspenProMVTM which provide the means to achieve more profitable and scalable outcomes.

The first application to explore is Aspen Mtell (Mtell) which actively promotes a ‘three zeroes’ strategy. Understandably executives at all industrial companies want to invest in products that support the "three zeroes strategy:"

- Zero casualties

- Zero environmental incidents

- Zero breakdowns

The Three Zeroes Strategy supports the AspenTech mission to assist customers in the direct support of corporate social responsibility (CSR) initiatives through activities helping to advance overall equipment effectiveness (OEE). As indicated earlier, overall manufacturing performance includes much more than profitability alone, so how can Mtell assist in managing the zero for safety and the zero for environmental incidents? First, from a compliance perspective, proper safety and environmental conduct is crucial to maintaining a manufacturer’s license to operate. Lack of performance there may have dire consequences. The equipment must run reliably and safely without environmental issues. Early understanding and correction of issues is paramount.

For over 90% of its operating time, a plant will run smoothly with few disturbances, which process operators can easily manage. Transient, changing conditions occur far less often, but exert the greatest stress on the plant and its operators, and can adversely affect personnel safety and environmental performance. While planned startups and shutdowns present some risk, they are usually prepared and planned for in advance, with training and procedures to execute them appropriately, The worst and most dangerous scenarios are unplanned shutdowns due to equipment breakdowns, when the bulk of all crisis situations occur. Unlike planned startups and shutdowns, during breakdowns there is no clear prepared plan to manage precarious moments. Without a plan in place, it is difficult to keep staff safe and avoid potential spills or gas flaring.

The extreme early warning is the first advantage in Aspen Mtell predictive applications. With warnings in weeks and months, not just hours and days, the cutting-edge AI-based condition monitoring in Aspen Mtell will announce well in advance if an incident is likely to occur, giving the time to plan a safe and environmentally secure shutdown. Such timing promotes a CSR win since an unplanned breakdown becomes an orderly planned shutdown with minimum impact on safety, the environment, and profitability.

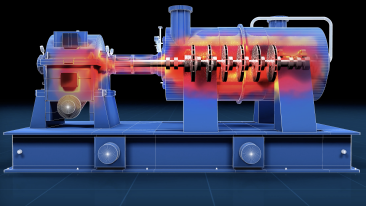

Furthermore, Mtell doesn’t just tell the user what’s going to happen in the future, it can also tell a user what to do to mitigate or completely avoid the circumstances – another CSR win. The Mtell facility for prescriptive advice leads to early corrective action to avoid an issue completely, or at least mitigate the consequences. The application may inform the user that an early minor repair will prevent a major crisis later, such as replacing a lube oil system filter, which left unattended would lead to a bearing failure and unanticipated breakdown. Another CSR win on environment and safety, plus lower maintenance costs and increased availability and profitability.

Prescriptive maintenance technology can advise the steps to take to stay safe and environmentally guarded during and after a disastrous breakdown. Such technology can advise what’s wrong, the root cause, and the scope, cost, and time required for service and repair. A further CSR win with precise advice and action and lots of warning time. Mtell casts a wider net to monitor and inform of spurious operating conditions that are damaging equipment and immediately, in real-time, advises precise steps to change the operation accordingly. The avoided damage and breakdown keep the equipment running under normal conditions without shutdowns, and potential, related safety and environmental issues, resulting in another CSR win.

In addition to such benefits, introducing the Aspen Fidelis solution increases possibilities for CSR improvement. Fidelis technology recognizes the individual pieces of equipment and how they are arranged and related in a whole system. It understands how mechanical and operating decisions affect forward-looking risk and the cost of different choices of action. When a warning declares a major machine has an unavoidable mechanical degradation and will fail in 50 days, Fidelis can forecast the risk in delaying the shutdown for 10 days, 20 days or 40 days. What does it mean to execute changes at different times based on parts availability, maintenance personnel convenience, and operating profitability? Fidelis will provide advice to steer the optimal balance of risk and cost. Once such information is known, operations, reliability/maintenance and marketing/logistics departments can collaborate to determine the correct course of action that minimizes safety and environmental impact as and includes risk and costs. Fidelis can provide additional CSR wins since coordinated planned action maximizes productivity in undesired circumstances.

Especially in chemical companies, the CSR mission increasingly targets reductions in off-specification products and inherent waste. Within the APM portfolio, the Aspen ProMV solution helps companies improve their yield and quality and reduce waste and intermediate product recycling by constant monitoring and correction of production processes. ProMV can inform and predict when changes in the manufacturing process are likely to end up with spoiled, wasted product and provide prescriptive advice on what operating parameters to change, and by how much, to assure the product remains on target. The result is less waste, less recycling, less energy usage and a lower carbon footprint – all harbingers of superior CSR performance. Such performance changes can apply equally well to batch and continuous processes.

Making it happen is more than technology – which is never enough to “move the needle” alone. The requisites are proven technology (not a science project), a simple, easy and rapid implementation methodology, and the appropriate work process to react to alert conditions. AspenTech works as diligently as possible to make it easy, to build with the customers current work skills in mind, and to fit with already established customer work processes.

AspenTech APM applications avoid unexpected breakdowns, reduce waste and off-spec products, reduce process disturbances resulting in great improvements in safety and environmental performance, besides minimizing losses and improving productivity. Leading companies are forging ahead with AI-based APM technologies that greatly improve their profitability, competitiveness, and social conscience.

CSR is not just about sustainability to improve operational efficiency and lower production costs. Corporate Social Responsibility includes three impact areas: social, environment and profitability.

- Social impact – take care of the people inside and outside of the business

- Environmental – do no damage and pursue reduced environmental impact

- Financial – align stakeholder values with sustainable business practices for long- term profitability

For more information about our Asset Performance Management Suite, visit our solutions page.

Leave A Comment