Have you ever been disappointed in a purchase or the outcome of a project because you did not have enough information or the right tools? Have you tried and failed to do a home renovation project and had to hire a professional to do it a second time, doubling the cost? Things often go differently in real life than they do in our heads. Likewise, the saying “You get what you pay for” is entirely true in most cases. The same holds true in industrial IoT.

Because industrial IoT is relatively new, most people are newbies to IIoT projects. Like any new project, it’s important to have the right information to make the best decisions. To date, the biggest challenges with industrial IoT is setting expectations for those with MES experience moving into the cloud. In most cases, users expect the same from IIoT as they do from MES: 100,000 sensors sampled at one-second scan rates, and the data sent into the cloud using an IIoT edge device with massive scalability and endless compute power.

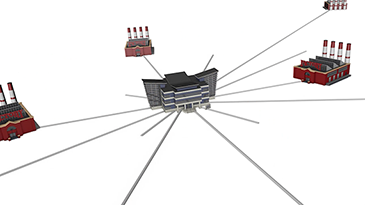

This notion is not entirely incorrect, but in some cases, the approach can be challenging. The belief that an IIoT edge device can handle this bandwidth means it’s time to put on our “IIoT goggles” so we can see things a little more clearly. Not every edge device is equal in its capabilities, and there are several other factors that play into the capabilities of IIoT.

When executing an industrial IoT project, it is important to know the facts about the edge devices, industrial protocols, sensors, networks and costs to avoid misalignment on expectations. Edge devices have a wide variety of features, with costs that range from a few hundred dollars to several thousand dollars. Other big costs can come from network usage when cellular or satellite is involved, as well as the storage costs of the cloud. In most cases, there are costs involved no matter how we choose to optimize for maximum value.

Managing expectations is an important aspect of any IIoT project. For example, it’s essential to understand that if a cellular edge device has low power consumption and low onboard resources, we should not attempt to jam 10,000 sensors data through it into the cloud. (Possibly 100 sensors, but not 10,000.) If 10,000 are required, then adequate resources are necessary for the interface between the sensors and the cloud, including the bandwidth of the network.

Along with the throughput expectations for IIoT edge devices, there are also expectations around security. There are never any guarantees with anything — just best-in-class practices and procedures. Secure IIoT is a combination of using the proper hardware + software + installation + secure communications. When these are all part of an IIoT project, the security risk has been minimized.

It’s critically important to have realistic expectations and a strong understanding of industrial IoT edge devices when executing an IIoT project. It’s also crucial to have the right equipment and services in place to meet the requirements to avoid unnecessary costs.

To learn how AspenTech can kick-start your IIoT initiative, check out the Aspen Connect family of solutions.

Leave A Comment