The winds hold a valued place in the identity of Italy. Dating from antiquity, the eight famous Italian winds have been important to mariners navigating Italy’s waters – especially the Mediterranean Islands.

For Sardinians, the Maestrale (or Maestro), a cold northwest wind which blows across Sardinia from France, holds a special place in their culture.

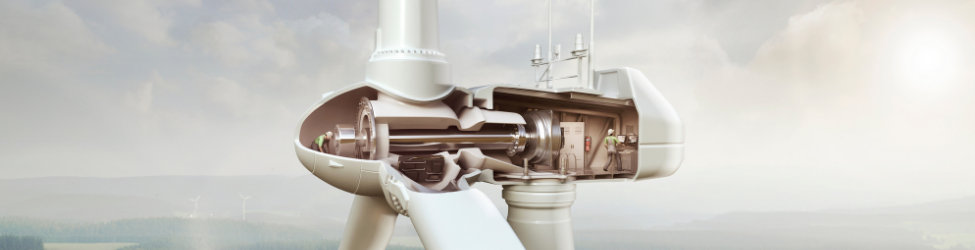

But when Sardeolica Srl., SARAS’ renewable energy subsidiary began producing electricity from a 57-wind-generator wind farm located in Sardinia, they turned to the most modern of solutions, Aspen MtellTM to bring a new digital paradigm for increasing up-time and energy production from the wind to new heights.

The key is Aspen MaestroTM for Mtell, a new innovation in the Aspen Mtell solution set which has enabled AspenTech and SARAS to team up together and deliver in a short period of time a highly accurate set of machine learning agents that predict wind turbine equipment degradation up to 180 days in advance.

The key is Aspen Maestro for Mtell, a new innovation in the Aspen Mtell solution set which has enabled AspenTech and SARAS to team up together and deliver in a short period of time a highly accurate set of machine learning agents that predict wind turbine equipment degradation up to 180 days in advance.

AspenTech’s unique Aspen Maestro for Mtell is a feature engineering solution (in machine learning vernacular) that automates the data preprocessing needed to train the Aspen Mtell Industrial AI solution on a new business domain, in this case wind farm generators. This enabled Sardeolica to rapidly develop the machine learning agents for the wind generator and gearbox equipment that provide advance notice of issues. After quickly seeing how the solution forecasts problems up to six months in advance, Sardeolica accelerated deployment of an initial pilot project, implementing prescriptive maintenance on 48 of the 57 wind turbines, taking advantage of Aspen Mtell’s advanced transfer learning capability to rapidly scale deployment of prescriptive maintenance across a large number of similar assets.

What has been the benefit to SARAS? Well, already the solution has resulted in a 10% reduction in maintenance costs. But more importantly, the six-month lead time has enabled scheduling of maintenance to be executed during low wind periods, thereby increasing up-time overall but also ensuring that maintenance downtime falls during the lowest wind potential period, maximizing electricity generation and revenue from the wind farm.

What does the future hold? Further instrumentation of the wind farms to extend the predictive capability to wind power transformers is already in planning. And longer-term benefits may include the ability to extend the lifetime of these capital-intensive systems.

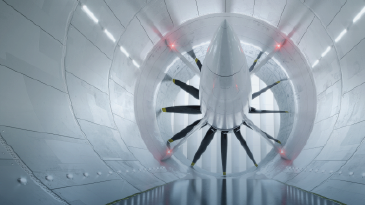

More and larger wind farms are in the capital investment pipeline. The US government has just announced a program aimed at opening leases for larger scale offshore wind farms across the entire US coastline. More wind farms are in development in Northern Europe, South America and other windy regions. These new assets will have long operating lifetimes ahead of them.

The quest for wind energy generators is for high reliability. The ability to proactively plan wind generator maintenance and improve the overall up-time and reliability of wind farms is good news from a public impact perspective. Broad implementation of machine learning technology such as Aspen Mtell and Aspen Maestro across renewables assets will increase reliability overall, improve ability to predict up-time and improve public confidence in the reliability of these relatively new technologies.

Whether it’s the Maestrale, Siciliy’s cold northwest wind, or Keewaydin, North America’s steady northwest wind, wind is growing in significance in the global energy transformation picture. And the up-time and reliability of ever more sophisticated wind generators is increasing in significance. As digital innovator SARAS found, machine learning in general, and Aspen Mtell in particular is proving to be a key tool to unlock new levels of availability and reliability in the globe’s wind farms.

TO LEARN MORE: Read the case study, Sardeolica Digitalizes Wind Farm Maintenance and our blog on how SARAS modernized its maintenance culture, You Can’t Fake Culture.

Leave A Comment