The problem virtually every maintenance person faces is having more maintenance to do than hours in the day. This situation can quickly snowball into more maintenance requirements than available man-hours and an out of control maintenance spend.

Too much maintenance comes from a variety of sources including:

- Emergency corrective maintenance (CM) from unexpected equipment failures

- Time-based maintenance instead of usage-based maintenance

- Over-maintaining equipment with preventive maintenance (PM)

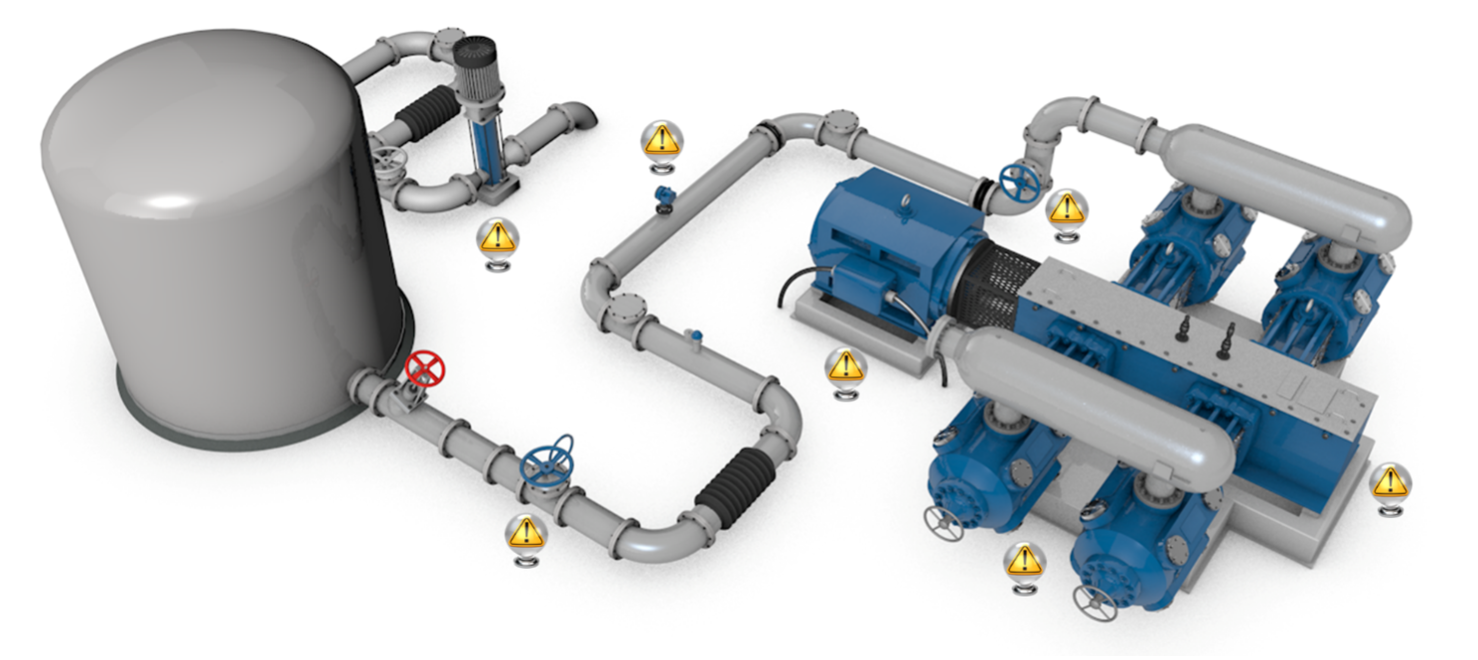

AspenTech’s APM solutions can help reduce the amount of required maintenance. Included in this portfolio is Aspen Mtell®, a predictive and prescriptive maintenance solution that can provide early warnings of potential failures using a series of agents to monitor equipment 24 hours a day. These can range from rules-based condition monitoring to machine learning agents that provide the earliest warning of failures. Aspen Mtell also monitors groups of sensors not only on the equipment, but upstream and downstream of the equipment. This allows it to monitor process conditions that can lead to failure, providing the earliest signs of possible equipment failure.

Once anomalies are detected, Aspen Mtell alerts and provides maintenance staff with information on potential failures and the sensor ranking of what led to the alert. In addition, when Aspen Mtell is trained on a previous failure, or agents are built around failure modes, it can provide prescriptive guidance on how to address the issue from either past experience documented in the EAM system or FMEA guidance.

Complimentary Solutions

Complimenting Aspen Mtell is Aspen Fidelis™, a risk based “what if” analysis tool that compares mitigation options for the alerts. It then provides the amount of risk and quantification (operations throughput and/or economic impact) for the various options to mitigate the alert risk. This information facilitates collaboration with operations staff to determine the optimal time to perform required maintenance at the lowest impact to operations and overall cost.

Aspen Mtell and Aspen Fidelis can also be utilized to optimize an overall maintenance strategy by evaluating the risk associated with extending or eliminating more standard preventive maintenance routines, further reducing the load on the maintenance teams. In addition, with the information provided by these solutions, the data and risk analysis becomes available to justify to Maintenance Management, Operations and Regulators for the optimization done on the maintenance routines.

Finally, Aspen Mtell and Aspen Fidelis can be utilized to prevent “over-maintaining” equipment by extending PM intervals or eliminating unnecessary maintenance altogether. As mentioned previously, with agents monitoring equipment and process sensors, round the clock monitoring of the equipment and process can provide early signs of potential failure. With this additional monitoring, the understanding of equipment usage and the maintenance previously performed, Aspen Fidelis can quantify the risk and cost savings of extending the intervals of overhauls or large expensive maintenance routines saving thousands of dollars in maintenance spend.

AspenTech’s APM solutions help maintenance personnel solve the long-time issue of having too much maintenance. Aspen Mtell provides predictive and prescriptive maintenance that delivers industry leading notice of potential equipment failure. By adding Aspen Fidelis’s risk analysis tool, maintenance strategies are further optimized by extending inspection intervals, and many times eliminating them entirely, giving maintenance personnel more time to focus on the required maintenance of critical equipment and reducing overall maintenance spend.

.png?h=250&w=975&la=ja&hash=B13DF91A3E4FC090D6FB68743C7D1CE4)

Leave A Comment