AspenTech and our Implementation Services Providers (ISPs) are helping customers on their supply chain digital transformation journeys. This month, I had the pleasure of catching up with Bob Hattersley, founder and owner of Opta Consulting Ltd., an AspenTech supply chain ISP.

Bob is a highly sought-after expert in supply chain planning, scheduling and optimization, and works predominantly with AspenTech’s European Supply Chain Management (SCM) customers.

Roch Gauthier (RG): Hello and welcome Bob. If you could, please share a bit about yourself and Opta Consulting and your expertise and experience in delivering Aspen Supply Chain Management (SCM) planning, scheduling and optimization solutions.

Bob Hattersley (BH): Thanks for the invitation, Roch. I’ve been doing optimization since I graduated from Cambridge University in the UK with a degree in mathematics and I have been delivering Aspen SCM planning and scheduling solutions for over 25 years. I first started to use Aspen SCM solution while working as a consultant at EDS and continued as a member of AspenTech’s professional services organization. In 2005, I left AspenTech and set up Opta Consulting. I have delivered Aspen SCM planning and scheduling solutions to clients across the process industries including oil and gas, power generation, pharmaceuticals, bulk and specialty chemicals, transportation, and food and beverages.

RG: I wanted to focus our conversation today on pharmaceutical end-to-end integrated supply chain planning optimization. Pharmaceutical supply chains have some complexities not present in other industries that must absolutely be considered during the supply chain planning optimization process. I’d appreciate it if you can share some deeper insights with our readers.

BH: A pharmaceutical company I work with and support has used Aspen SCM for global end-to-end holistic supply chain planning optimization for nearly 20 years. Their manufacturing is quite complex, requiring up to 10 processing stages, and relies on a key raw material out of which thousands of distinct products are produced. This pharmaceutical company has about twenty manufacturing facilities around the globe operating dozens of production lines, and the path that any one of their finished products follows, from the initial raw material, is extremely complex.

When you get into the details of their manufacturing processes, there are numerous unique constraints that one does not encounter in other industries. It is critical to model and respect these constraints as part of the end-to-end supply chain planning process.

The first type of constraint is related to batches or production lots. It is common in other manufacturing industries, such as specialty chemicals, that production batches will be of a fixed size or quantity. In their case, the size of their batches can vary considerably between an upper and a lower limit. Other critical constraints are related to shelf life, as some of their intermediate materials can only be stored for a certain time period before they expire. These constraints, and many others, are considered holistically during their global end-to-end supply chain planning optimization using Aspen SCM.

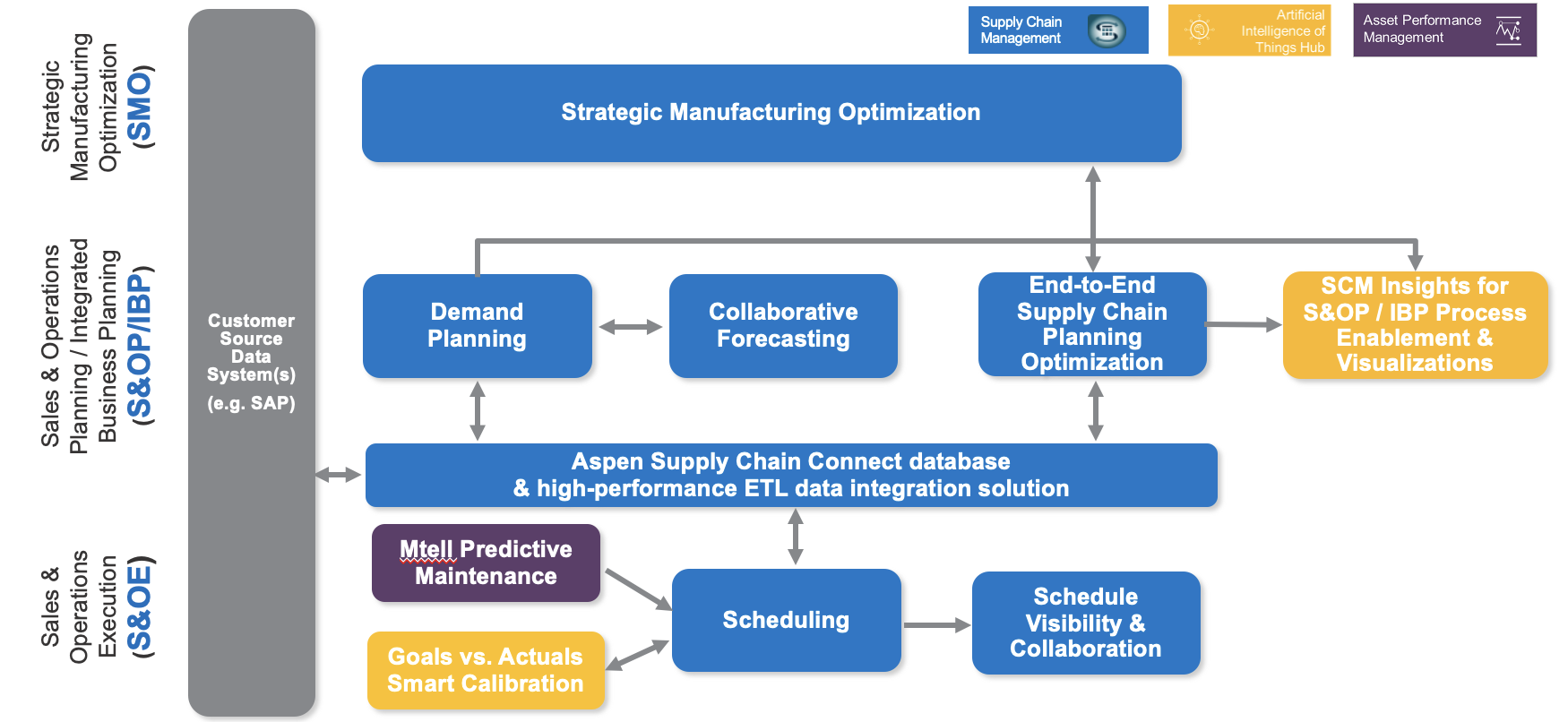

|

| Figure 1: Overview of aspenONE SCM solutions and synergies with other AspenTech suites |

RG: The planning solution you delivered for this customer makes use of mathematical optimization which allows them to plan across their global end-to-end supply chain as one holistic business system. Can you provide some insights on what the solution helps them accomplish?

BH: This pharmaceutical company relies on Aspen SCM to create the best end-to-end integrated supply chain plans, across a 36-month planning time horizon. The goal of an optimization model is to maximize or minimize some objective, subject to a set of constraints. The primary goal of this client’s optimization model is to get the stocks of their life-saving medicines to country warehouses where they are needed for their patients and make sure that critical safety stocks are maintained. The secondary objective of the optimization model is to determine the most cost-effective plan, across the 36-month planning horizon, by considering the marginal economics across their end-to-end value chain. Their global end-to-end supply chain model is solved holistically in Aspen SCM since we are leveraging Mixed-Integer Programming (MIP) optimization methods.

Aspen SCM allows them to do what no person could ever do, which is evaluating an astronomical number of possible end-to-end interrelated supply chain planning decisions spanning a 36-month time horizon and finding the best combination of decisions that maximizes the objective function and respects all the modeled constraints.

I recently completed an upgrade project for this client and migrated them to the latest release of Aspen SCM. At the same time, the client took the opportunity to move the solution from an older on-premise server to their new Amazon private cloud environment. They decided to make use of computing instances in AWS which are ideally suited for running High Performance Computing (HPC) applications, like Aspen SCM. The client and I were both pleased to see a 30-40% reduction in the time needed for Aspen SCM to determine the optimal end-to-end integrated supply chain plans, thanks to the new computing infrastructure. This was a great benefit because it allows the client to run a greater number of ‘what if’ optimization scenarios during their planning process.

RG: Bob, as an implementer of supply chain planning, scheduling and optimization solutions, what do you appreciate most about Aspen SCM and how does it benefit clients?

The most distinctive aspect of Aspen SCM is its configurability. This extends as far as unlimited customization of the MIP optimization model, along with configurable data management, user interfaces and reporting to support the extended model. Every pharmaceutical and specialty chemicals application that I have worked on has had some feature that is unique to the application. Without Aspen SCM’s flexibility, it would not have been possible to represent these features accurately, if at all, and the value to my clients would have been substantially reduced as a result.

RG: Bob, I want to thank you for helping our audience learn more about holistic end-to-end supply chain planning optimization in the pharmaceutical industries. If someone wants to connect with you, what’s the best way to get in touch?

BH: People can get in touch with me at bob.hattersley@optaconsulting.co.uk.

To delve deeper into the related topic of Pharmaceutical Scheduling and Execution watch this recent webinar titled “Riding the Rollercoaster of Pharma Production Scheduling,” featuring AspenTech’s Cade VanRooyen, a former Pharmaceutical Master Production Scheduler.

/110.png?h=250&w=975&la=ja&hash=2ECDCC23DF7849F7B497C55FE8947469)

Leave A Comment