I was fortunate to spend the first few years of my career in the global procurement group of a very large specialty chemical company. I learned a lot in that Houston area high-rise, but one key truth was that a vendor’s ability to have the chemical “where I need it, when I need it” frequently trumped minor cost considerations.

Trust is a critical component of any sales relationship, and if I could trust my vendor to go above and beyond when the odd emergency happened, then I would trust that vendor with my business year-round. Whether it’s next-day shipping on an Amazon package or a truckload of drums to west Texas, outstanding customer service shapes all our purchasing decisions.

In the last few years, there have been many significant changes in the chemical industry, one of which has been a strategy shift by many producers of base chemicals. With stagnant product innovation and few novel market opportunities, many chemical producers concerned about shrinking margins have moved their strategies away from base chemicals (and their volatile and direct feedstock impacts) towards specialty products. This means increased competition across the specialty industry and the ever-increasing pressure of commoditization in now-crowded market segments.

Leverage Technology to Turn the Challenge Into Opportunity

Few companies have the agility required to maintain margin when confronted by a segment challenger. I saw this recently with a line of oilfield chemicals. The products became commoditized seemingly out of nowhere, and it took the organization well over a year and a half to respond with a competitively priced product through an optimized supply chain (Note: competitively priced, not lower-priced). Once commoditization occurs, the previous margins are no longer attainable, and an organization finds itself competing on price.

How, then, can a company differentiate itself from its competitors, build trust and ensure business retention and growth? One way is by providing responsive, agile customer service. However, this type of outstanding customer service is easier said than done. In fact, the current state of the specialty chemical industry suggests the “deck is stacked” against great customer service.

Growing complexity, shifting labor markets and the incredible pace of technological change create huge challenges — but also huge opportunities. Never has an organization, from CEO down to scheduler, had the types of powerful, customer service-enabling tools available that they have today.

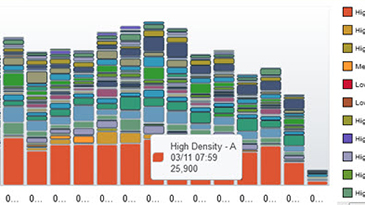

One such tool is Aspen Plant Scheduler™, in use at close to 300 specialty chemical manufacturing sites worldwide. With Aspen Plant Scheduler, you can model your unique physical assets while creating optimized executable schedules.

Last-minute customer order? No problem! With visual drag-and-drop schedule-change capabilities, schedulers can update production and generate an executable schedule in minutes. Built-in demand prioritization ensures your demand mix always meets the needs of internal and external customers — even when that demand mix is in constant flux. One valued customer, Momentive, achieved a 30 percent increase in its on-time order fulfillment utilizing Aspen Plant Scheduler.

To learn how Aspen Plant Scheduler can help your organization build trust with customers and achieve outstanding levels of customer service, view our series of short demonstration videos.

If you would like more information on AspenTech’s supply chain management offerings, please email supplychain@aspentech.com.

Leave A Comment