The process industries are going through a new era of digitalization, and companies are looking for solutions that can make an immediate impact to their operations while providing high returns. With today’s release of aspenONE® Version 11 software, our customers can take a big step forward in their digitalization journey by closing the gap between planning and actual operations.

The aspenONE V11 release features exciting innovations across the Engineering, Manufacturing & Supply Chain, and Asset Performance Management software suites, and it also introduces Aspen GDOT™, a new generation of dynamic optimization technology that enables Unified Production Optimization in complex industrial environments.

In V11, we offer the power of vertically integrated solutions, enabling companies with batch and continuous operations to:

- Break down barriers between engineers, planners and schedulers

- Streamline operations to drive higher efficiencies

- Leverage analytics to increase throughput and uptime

- Improve margins with dynamic optimization across process units

- Rapidly develop competency for safe startup and operations

Unlocking the Value Across Industries

So how does this translate to business value for our customers? Well, it depends.

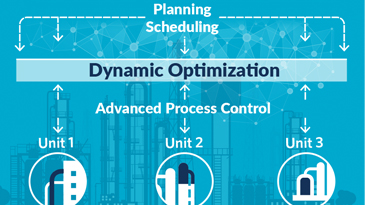

For energy and bulk chemicals customers, vertical integration enables Unified Production Optimization. This closes the loop between planning, scheduling and APC by dynamically optimizing multiple units in real time to ensure the best site-wide economic results. Additionally, it streamlines planning model updates from process simulation models calibrated with actual plant data to increase planning model accuracy.

The potential benefits are massive! Many refineries and olefins plants already use our planning and APC technologies. With the addition of dynamic optimization, AspenTech provides a closed-loop adaptive solution that can increase margins by up to $100 million per year for a mid-sized refinery.

For specialty chemicals, polymers, and pharmaceutical companies, it means aligning operations with market needs. This is done through a full range of digital solutions that synchronize manufacturing with customer requirements and accelerating time-to-market with improved end-to-end batch simulation models.

George Baartmans, senior manager of global supply chain and analytics solutions for Hexion, told us, “We anticipate a reduction in schedule upsets as we enable manufacturing to easily communicate schedule issues well in advance of them becoming production issues.”

For engineering and construction companies, this release enables them to improve engineering efficiency, boost profitability and reduce project risk. We have added capabilities that will not only help EPCs win more work, but also protect the margins on those projects. With greater insights into potential sources of risk in the project, firms can put their resources in the right areas to avoid the problems that eat away profits and cause schedule delays.

Enabling Critical Capabilities

For the first time, prescriptive maintenance is now incorporated into planning and scheduling. Why is this significant? Because it allows you to see the future, warning of future equipment condition issues so that you can plan interventions for asset failures and quality issues.

Not only does this allow for a shift from reactive to proactive behavior, but it can actually lead to the planner or scheduler making different decisions than they would have without advanced warning of potential failures.

aspenONE V11 is a significant point of progress along AspenTech’s innovation journey to unlock value, delivering a full range of integrated digital solutions that improve margins, increase production, and drive higher utilization and performance. This is the next step in our commitment to providing digital solutions that further improve our customers’ profitability.

Want to see all of the new V11 capabilities in action? Join us at our signature user conference, OPTIMIZE 2019! You’ll get the chance to experience the new V11 products and innovations through customer presentations, industry and best practice training sessions, integrated demos in our Innovation Lounge and more.

Don’t miss out! View the detailed agendas and register here.

You can also learn more about what’s new in V11 here.

Leave A Comment