.jpg)

Looking for ways to improve profit margins?

Visit our NEW Aspen HYSYS Resource Center! Learn how Aspen HYSYS provides powerful capabilities that simplify and improve petroleum refining simulations. This resource center will help new and experienced engineers discover the full power of Aspen HYSYS, the most trusted process modeling software for the energy industry.

Increase profits with better feedstock selection.

Increase your profits by 5% with heavy crude process modeling using the Visbreaker and delayed coker model – calibrated to match your refinery – along with improved crude assay characterization.

Improve operations and profit margins.

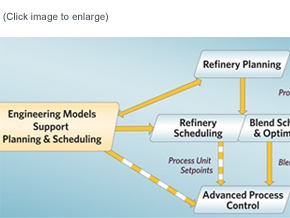

Reactor models in Aspen HYSYS® Petroleum Refining can be dragged and dropped onto a flowsheet like any other Aspen HYSYS® unit operation and quickly integrated into a larger flowsheet. They provide accurate data for the support of the reactor models in the refinery LP planning model (e.g., Aspen PIMS) to improve refinery crude feedstock selection and plant-wide optimization.

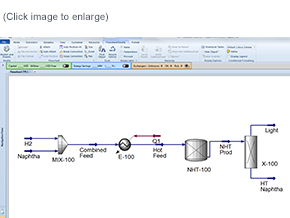

Aspen HYSYS® Naphtha Hydrotreater

Aspen HYSYS® Naphtha Hydrotreater is a rigorous kinetic model that can be used to model the processing of naphtha feed streams to catalytic processes, such as the naphtha reformer or isomerization unit. Removal of olefins, sulfur, and other contaminants from naphtha streams to prevent poisoning and degradation of catalysts in downstream units can be easily simulated using the Naphtha Hydrotreater model.

Aspen HYSYS® CatGas Hydrotreater

Aspen HYSYS® CatGas Hydrotreater model is a pair of models that simulate the processing of gasoline streams that are fed directly into the blending pool from other major process units, typically the FCC. The pair of models is comprised of a selective hydrogenation unit (SHU) designed to remove di-olefins and convert sulfides in order to clean the lighter part of the naphtha. The second unit of the pair is a specialized hydro-desulfurization (HDS) unit designed to remove sulfur and other contaminants while preserving the octane number.

Aspen HYSYS® Alkylation

Aspen HYSYS® Alkylation refers to two new models to simulate Alkylation processes: one for sulfuric acid-based alkylation and one for hydrofluoric acid-based alkylation process. These rigorous models can be used in the Aspen HYSYS® flowsheet like any other unit operation. The models can be calibrated to plant data and used to update LP submodels for refinery planning.

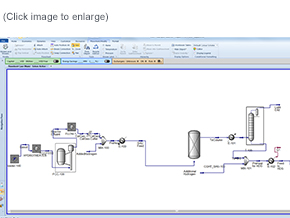

Aspen HYSYS® CatCracker

Aspen HYSYS® CatCracker is used to simulate a refinery FCC reactor (Fluid Catalytic Cracker) unit. The core model is a rigorous reactor and regenerator flowsheet with multiple lump reactor kinetics, rigorous regenerator coke burning kinetics, and heat balance between the reactor and regenerator via the catalyst circulation. Reactor models are open and customizable by the user, and are fully integrated with the Aspen HYSYS® process model. There can be multiple configurations for the FCC reactor and regenerator system. All major operational FCC reactor variables are available such as feed rate, feed composition, feed temperature, reactor outlet temperature, catalyst activity, catalyst type, catalyst cooler duty, etc.

Aspen HYSYS® Hydrocracker

Aspen HYSYS® Hydrocracker is a rigorous reactor model that simulates hydrocrackers and hydrotreaters consisting of reactor beds and associated recycle gas quench streams. This multiple-lump hydrocracker reaction system can be used like any other Aspen HYSYS®unit operation. It provides accurate data for the support of the hydrocracker and hydroprocessor submodels in the refinery LP planning model (e.g., Aspen PIMS) to improve refinery crude feedstock selection and plant-wide optimization.

Aspen HYSYS® Reformer

Aspen HYSYS® Reformer is a rigorous reactor model that simulates a naphtha reformer producing reformate for gasoline blends in refineries. This multiple-lump reaction system can be used like any other Aspen HYSYS® unit operation. It provides accurate data for the support of the reformer submodels in the refinery LP planning model (e.g., Aspen PIMS) to improve refinery crude feedstock selection and plant-wide optimization.

Aspen HYSYS® Delayed Coker

Aspen HYSYS® Delayed Coker provides a rigorous model in the refinery reactor suite that simulates a coker that can be fully calibrated and used to update PIMS submodels for improved optimization. Eliminate heavy crude processing bottleneck, optimize product yields and keep track of coke production and product specifications by modeling your delayed coker.

Aspen HYSYS® Visbreaker

Aspen HYSYS® Visbreaker provides a rigorous model in the refinery reactor suite that simulates a visbreaker that can be fully calibrated and used to update PIMS submodels for improved optimization. Eliminate heavy crude processing bottleneck, optimize product yields and keep track of coke production and product specifications by modeling your visbreaker.