Save on in-plant projects.

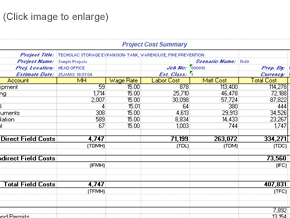

Aspen In-Plant Cost Estimator is a powerful tool for capital and maintenance projects where an existing process or facility infrastructure is in place. With this cost estimating software, users can develop detailed designs, estimates, and schedules with minimal project outlines. Learn more about how Aspen In-Plant Cost Estimator generates capital expense (CAPEX) estimates that can help your company reduce risk and uncertainty when undergoing capital and maintenance projects with the brochure below.

Utilize industry-leading project management capabilities.

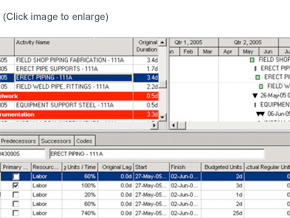

Make use of an embedded link to the Primavera to generate a logic-driven CPM complete with activities, durations, manpower, and costs. Each activity is linked to predecessors and successors, and is loaded with resources (costs, effort hours, crew mixes).

Access user data for estimation support.

Aspen In-Plant Cost Estimator can link to any customer data source for unit cost data, further improving the accuracy of estimates. This cost data can be used to generate accurate estimates for capital projects in oil and gas, refining, and chemicals.

Integrate with the Economic Evaluation suite.

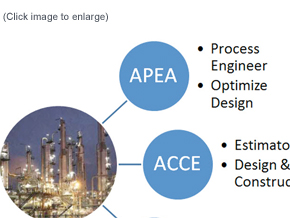

Based on the same Aspen Icarus technology in both Aspen Process Economic Analyzer and Aspen Capital Cost Estimator, Aspen In-Plant Cost Estimator is a core element of the Aspen Economic Evaluation cost estimation software family.

See how customers have profited from Aspen In-Plant Cost Estimator.

View how customers have directly benefited from using Aspen In-Plant Cost Estimator for their estimating challenges.

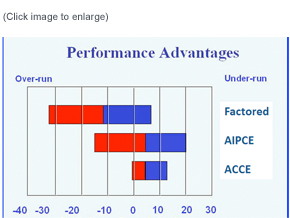

Using AspenTech’s cost estimation software, PEMEX, Mexico’s National Oil Company, exceeded industry benchmarks for AACE Class IV and Class II estimates for capital projects in Oil & Gas, E&P, and refining.

View training resources for Aspen In-Plant Cost Estimator.

AspenTech offers many ways for you to learn how to use Aspen In-Plant Cost Estimator to achieve your business objectives. Our instructor-led classroom and virtual classes are scheduled globally for your convenience. We also have an extensive E-Learning library which is accessible from within Aspen In-Plant Cost Estimator!