Improve your profits through rigorous models of all of your refinery reactors.

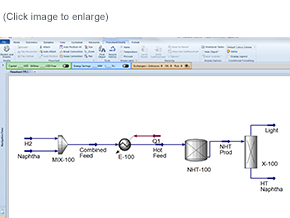

With the addition of the new Naphtha Hydrotreater and Alkylation unit models, Aspen HYSYS Petroleum Refining now has a complete suite of rigorous kinetic models to support all major refinery processes. Accurately model all complex refining processes in the easy-to-use Aspen HYSYS environment. Make better planning and optimization decisions with the support of calibrated reactor models.

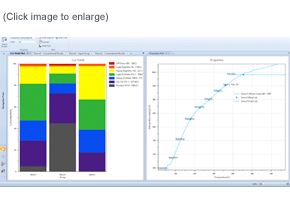

Characterize and Analyze crude assay data with the breakthrough Assay Management technology in HYSYS Petroleum Refining.

Easily evaluate and model the effects of crude feedstock selections in the refinery engineering processes with the new Aspen assay management in Aspen HYSYS Petroleum Refining. Access hundreds of assays from a variety of regions in the assay library database for use in your process modeling simulation. Better predict crude properties with improved characterization methods, including molecular characterization, to improve decision-making.

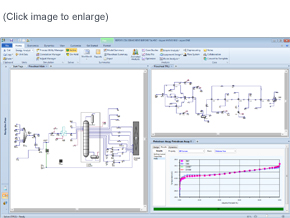

Optimize your refinery process using the full power of the aspenONE Engineering Suite.

Characterize crudes, analyze multiple feedstocks, track petroleum properties and carbon emissions, and leverage activated Energy, Economics and heat exchanger design and rating for energy optimization and maximized profits in refinery engineering processes.

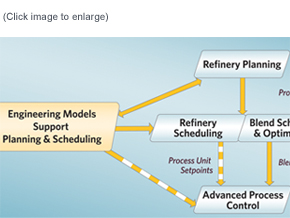

Update refinery planning and scheduling.

Aspen HYSYS Petroleum Refining includes tools to easily import and export petroleum assays to and from Aspen PIMS with the new Aspen Assay Management. You can also automate the export of rigorous reactor models to Aspen PIMS (LP software). This support improves Aspen PIMS accuracy, leading to better refinery feedstock selection.

Improve crude distillation unit modeling.

Aspen HYSYS Crude based models can be converted to Aspen HYSYS Petroleum Refining. The auto converted model can now access the full power of Petroleum Refining capabilities to quickly evaluate and optimize crude feedstock taking into account key properties such as Sulfur and Cloud point.